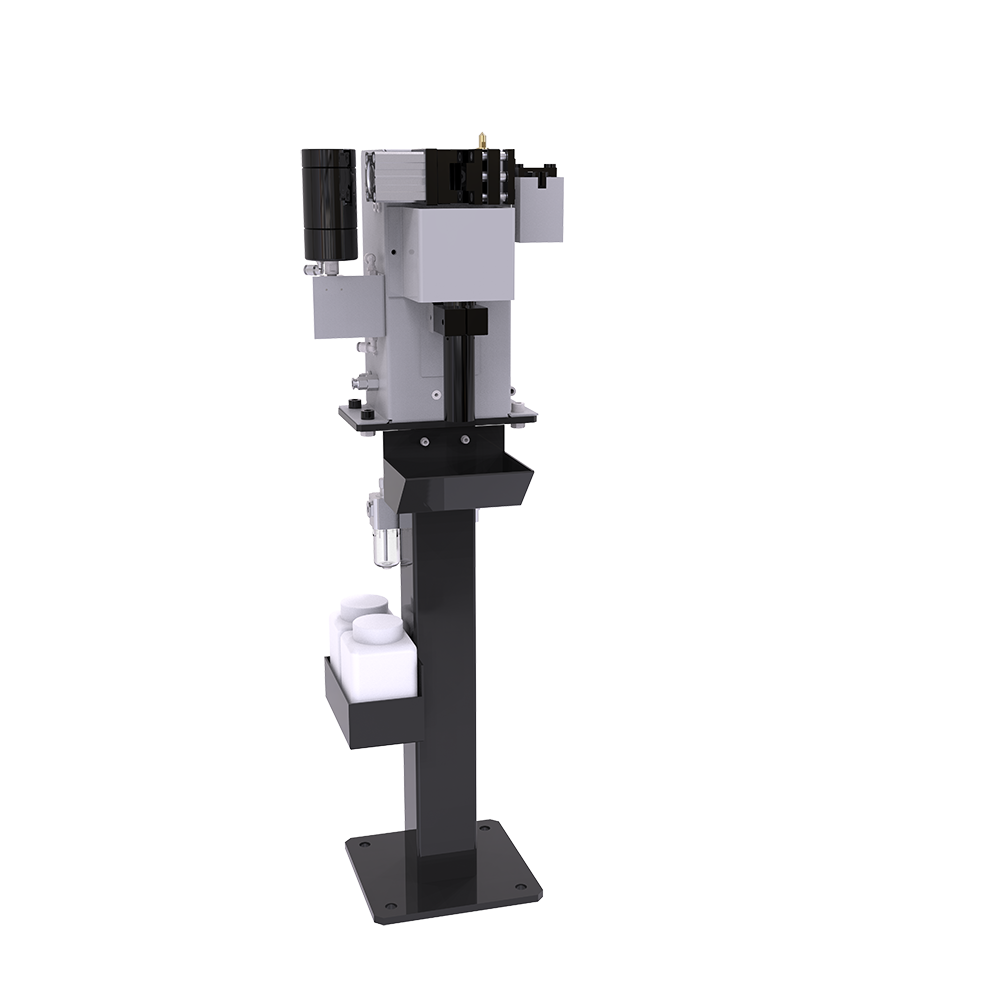

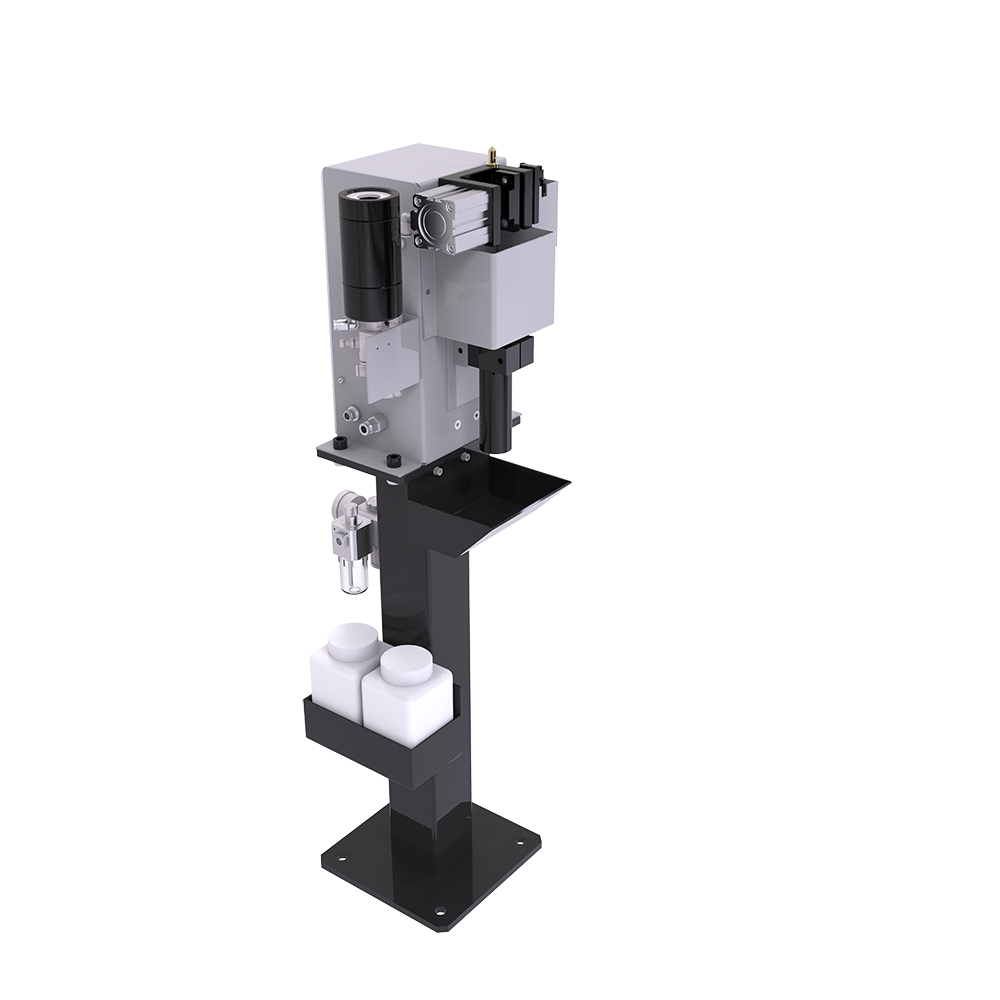

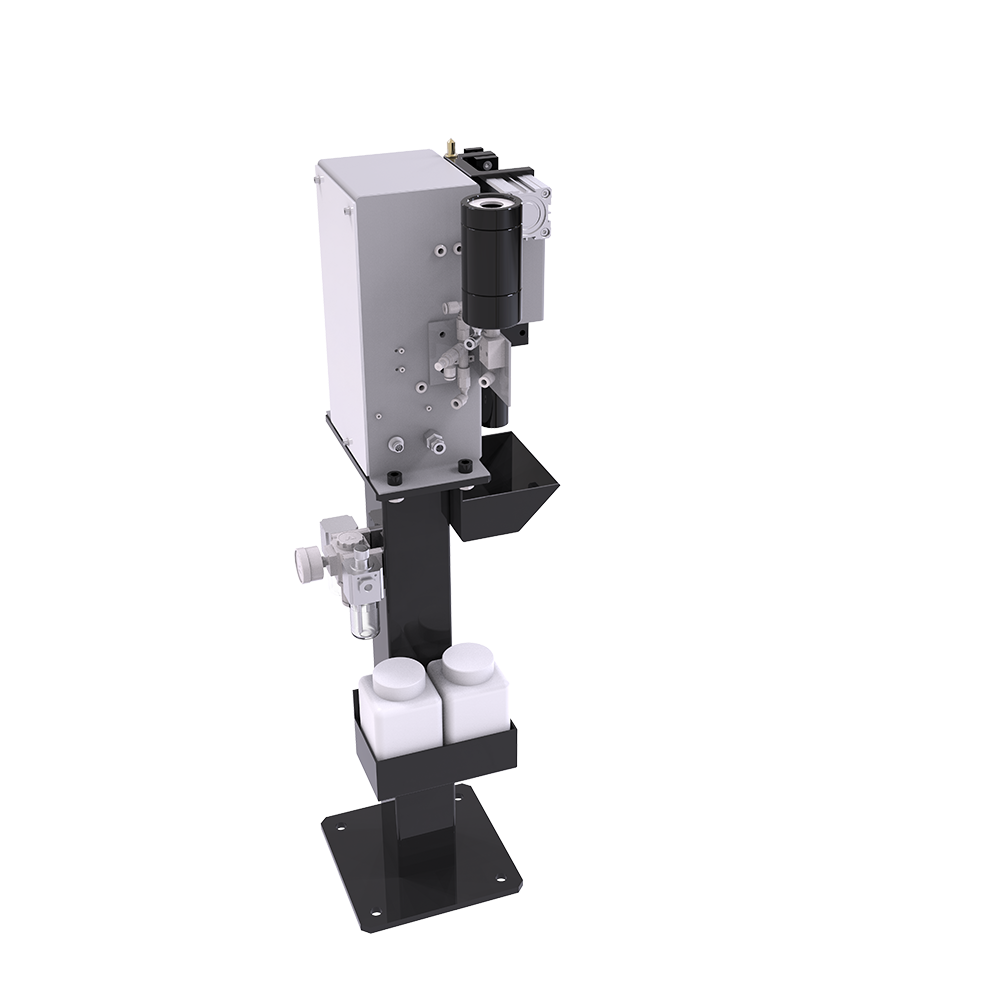

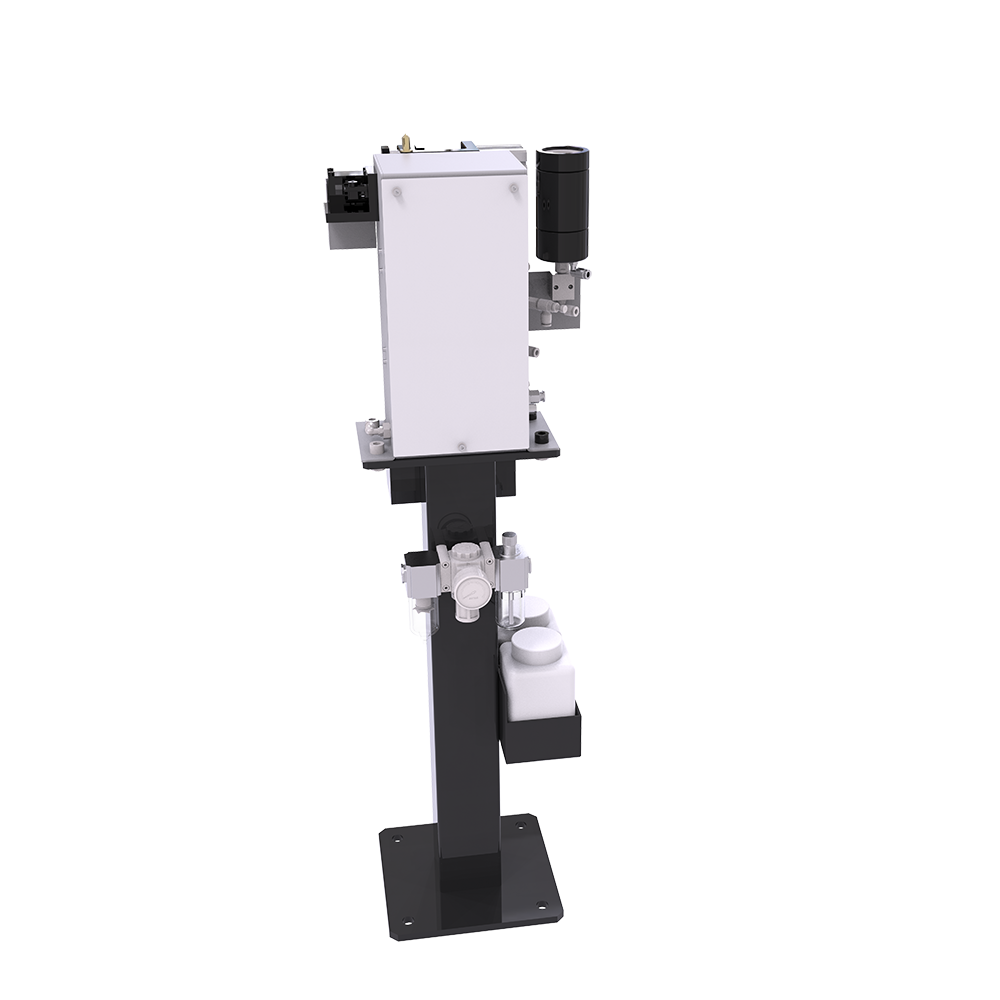

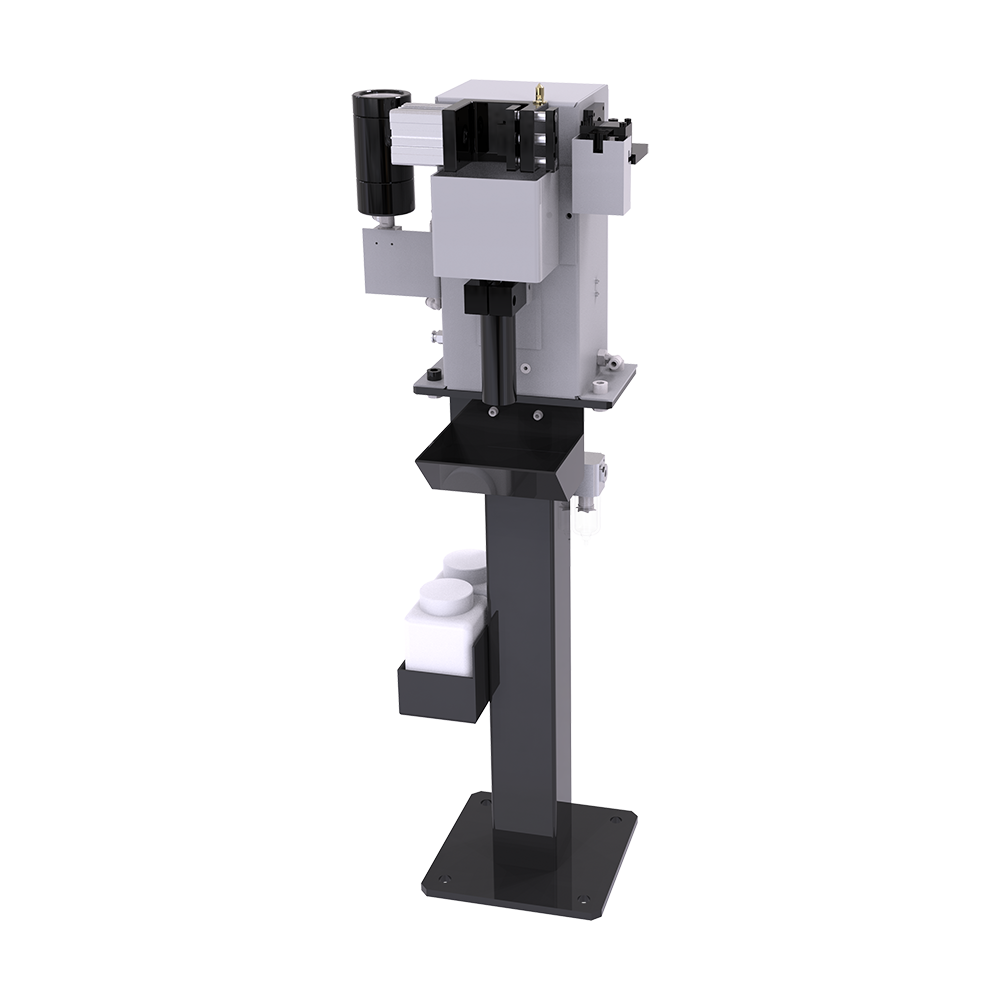

Robotic Gun cleaning station

Product Introduction

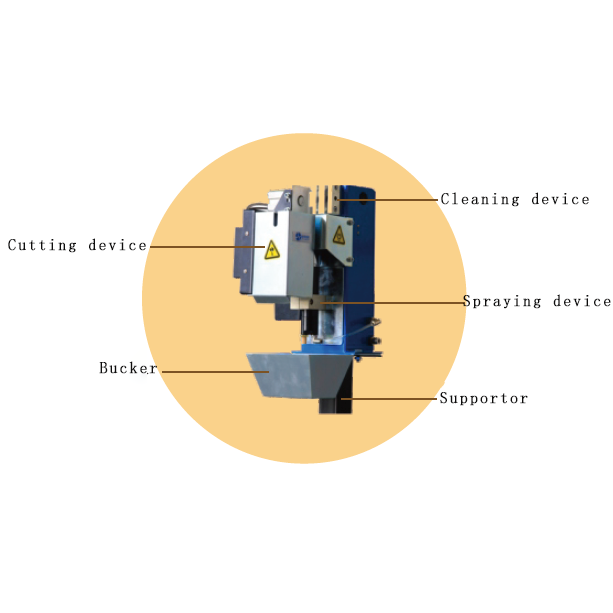

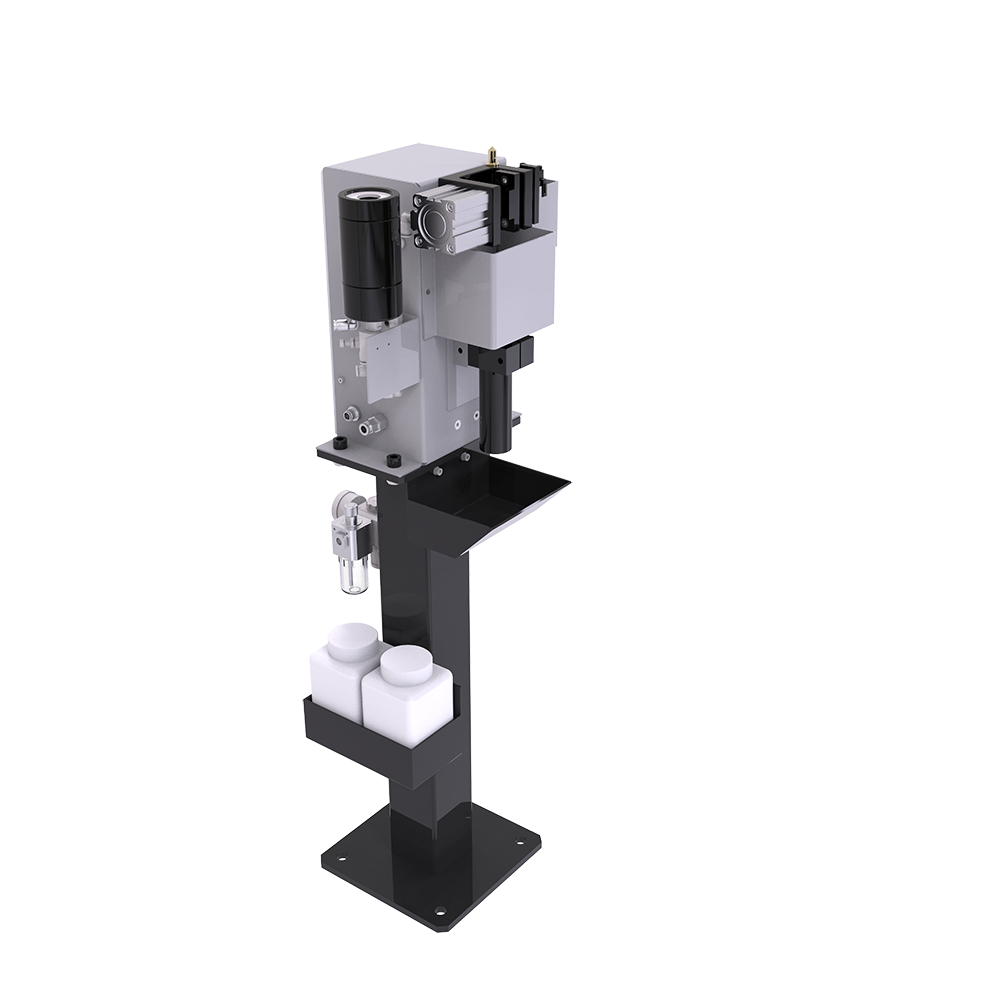

Automatic cleaning station is designed for the robot welding gun and automatic welding gun equipped with automatic welding system.The operation of the equipment is controlled by robot, and the equipment will provide the corresponding feedback signal to the robot.

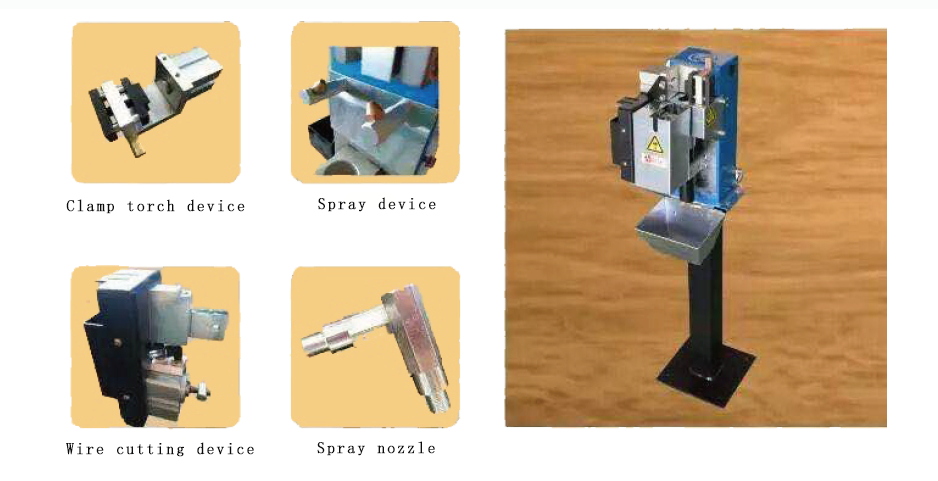

The cleaning station uses reamer rotation to remove welding slag and impurities from welding Torch head and welding Torch nozzle.The cleaning station is equipped with a complete oil injection structure, the welding Torch head can spray anti-splash liquid after the completion of cleaning, so as to reduce the probability of re-adhesion of welding slag.It is also equipped with an automatic wire cutting device, which is electrically triggered by the robot controller or mechanically triggered by the welding torch

Technology Parameters

|

Model |

HY2000S |

|

Compressed air |

Oil-free dry air |

|

The amount of air required |

10 liters per second |

|

process control |

pneumatic |

|

Voltage |

24 |

|

Cleaning time |

4~5 Second |

|

Anti-splash capacity |

500ml |

|

Anti-splash injection amount |

Adjustable |

|

Weight |

14kg |

Features

All high Quality products

1. The cleaning and oil injection design in the same position of the cutting mechanism of the cleaning Torch, the robot only needs one signal to complete the cleaning and oil injection action.

2. The cleaning station only needs 6-7 seconds to finish the whole cleaning process, compared with other similar products in 12 seconds, which greatly saves the cleaning time of the robot and improves the working efficiency of the robot.

3. The use of multifunctional reamer, cleaning torch can be to the root of the conductive mouth seat cleaning effect thoroughly.

4. Main components of the cleaning Torch wire cutting mechanism are protected by high quality casing, which is free from impact splash and dust.

5. The new type of oil injection device in the torch cleaning station is controlled by the robot through the solenoid valve.

6. The safe and reliable atomizing anti-splash agent can reach the root of the welding torch head very well. At the same time, the relatively closed oil injection chamber greatly reduces the oil mist pollution problem compared with old design

7. The wire cutting device is controlled by solenoid valve, and the wire cutting is more accurate.Make sure the cut wire falls into the collection box Compared with other brand products, the electrical layout is very simple, all the control elements are safely placed in the case, and there are very few exposed pipelines

DETAIL SHOW

All high quality products

CERTIFICATION

Official certified quality assurance

FQA

Q. Can your Nozzle cleanning staion be used for all robot?

A. Yes, it can be used for all brand of robot, like Kuka, Yaskawa, Fanuc, Abb, etc.

Q. What about the voltage of the welding gun cleaning station?

A. 24V

Q. How many Gun cleaner for welding robots can be supplied every month?

A. 100 ~150 units every month

Q. Does the torch clean station be used for wire cutting?

A. Yeah, it's one of the function. it can be used for Wire cutting, oil spraying and torch cleanning.

Q. is there any consumable parts for robotic gun cleanning station

A. anti-splash oil, wire cutter and ream.