Precision Reduction Gear RV-C series

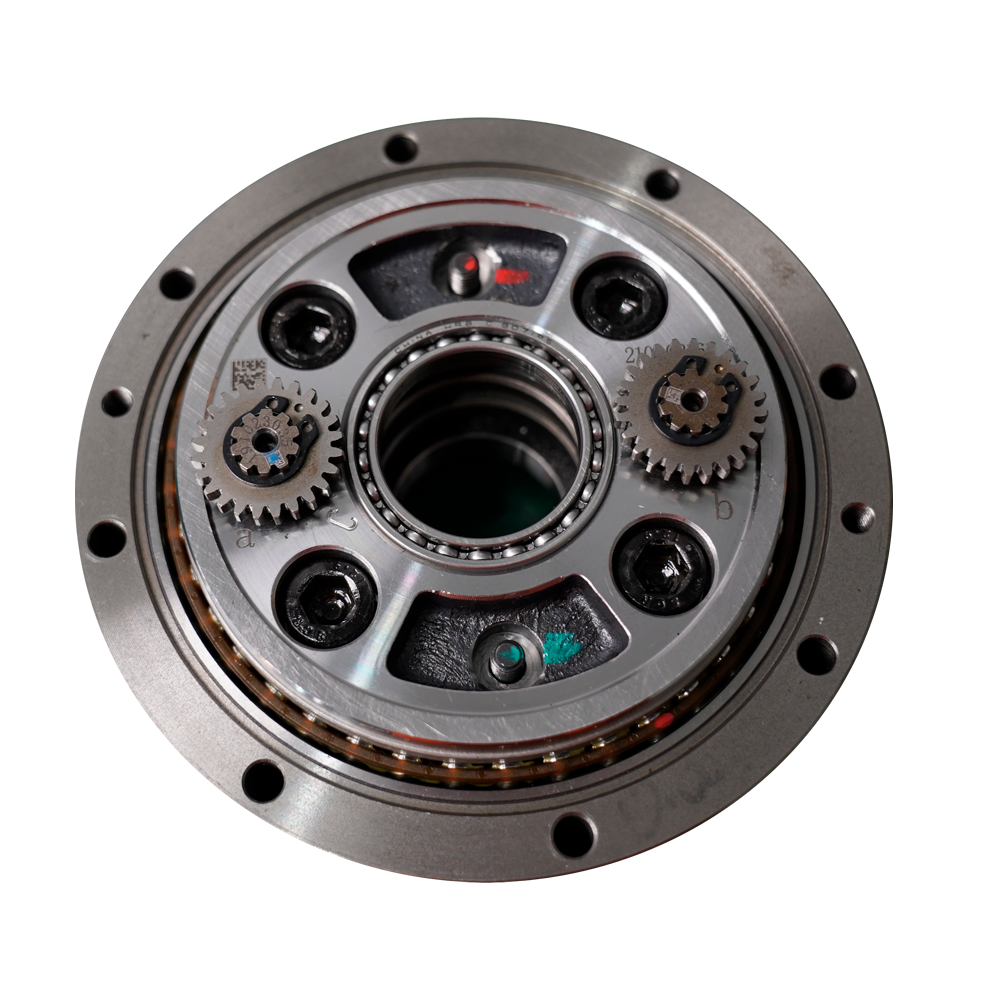

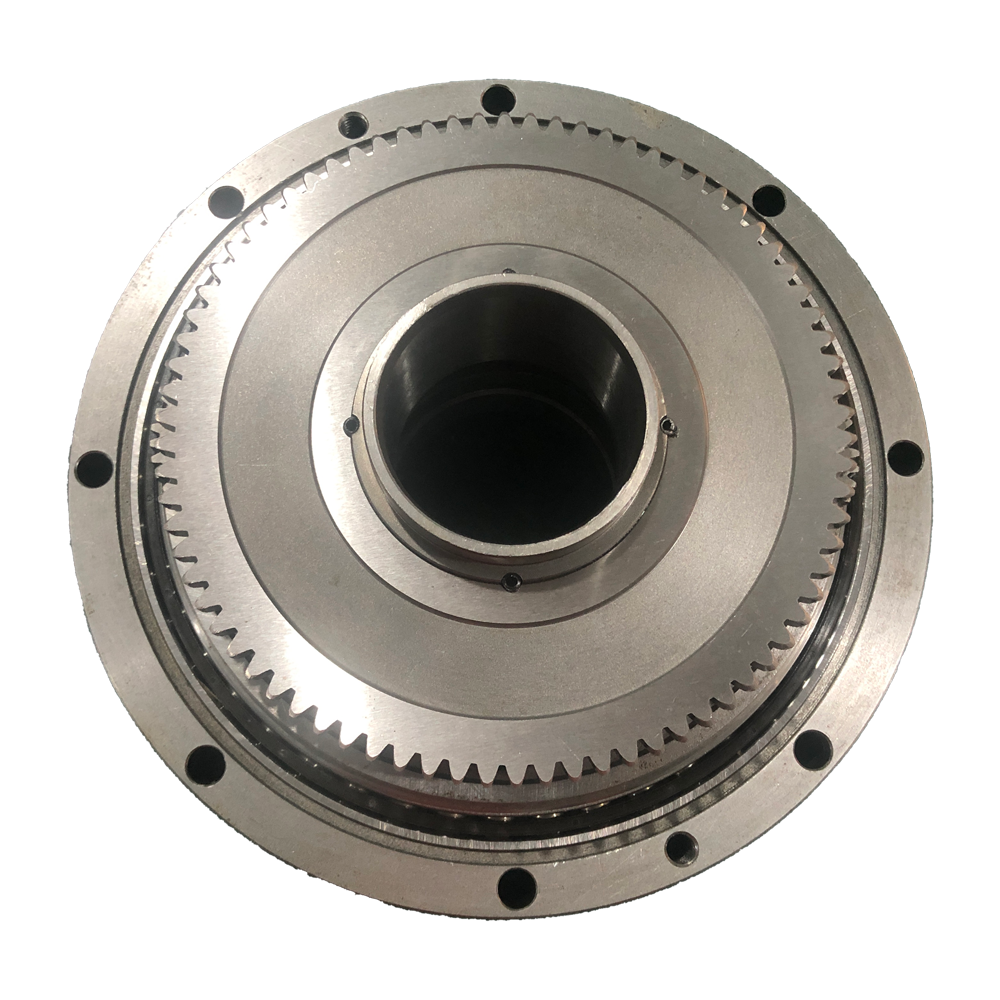

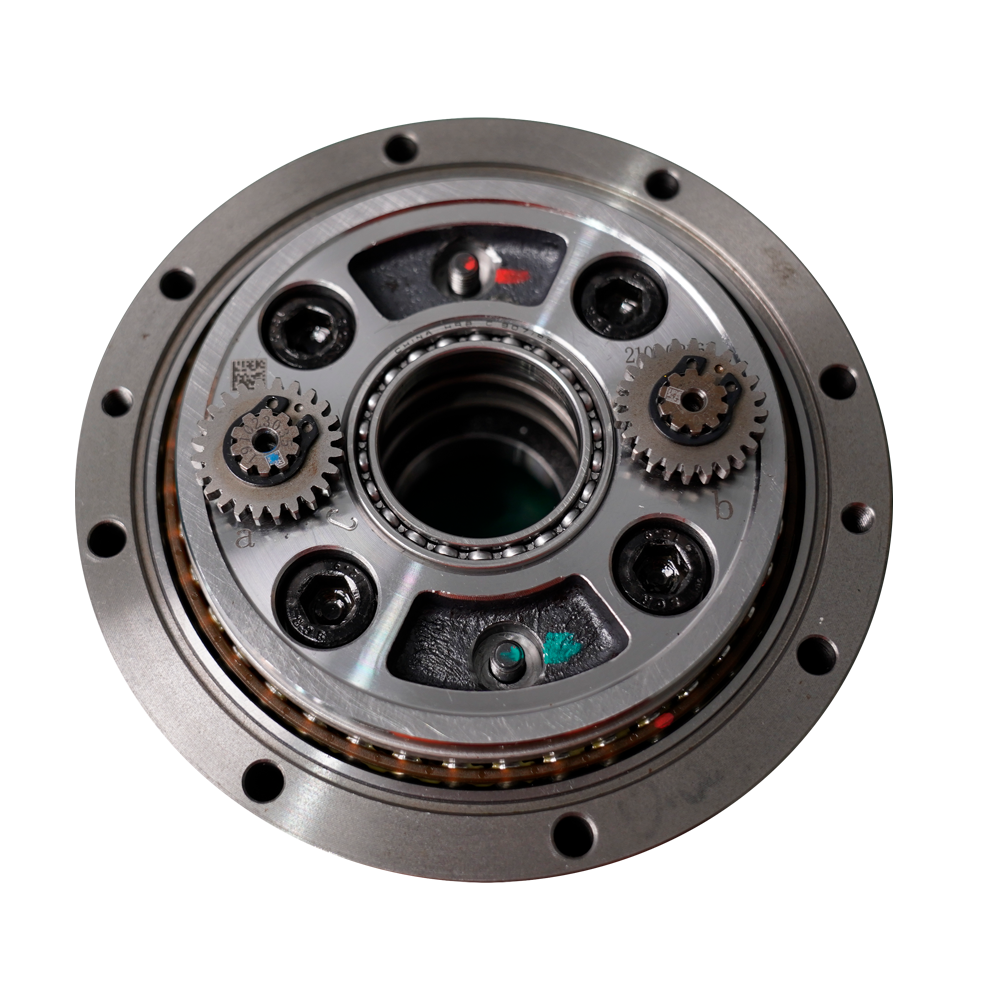

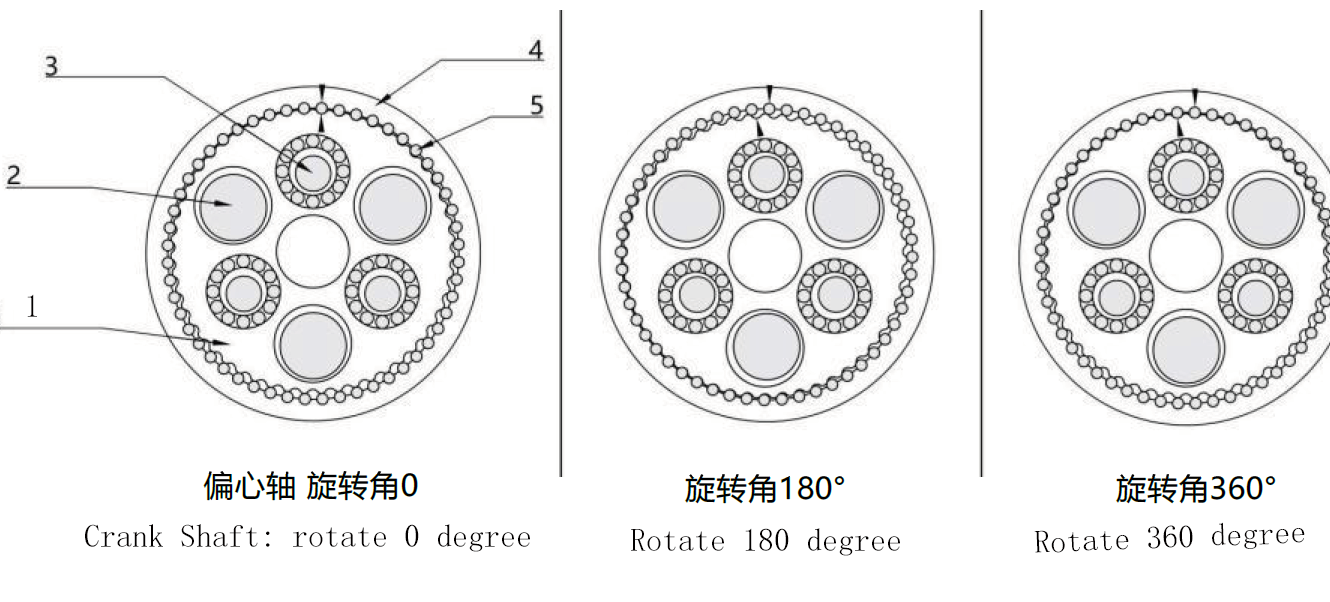

Operating Principle

1. Cycloid disc

2. Planetary gear

3.Crank shaft

4. Needle house

5. Pin

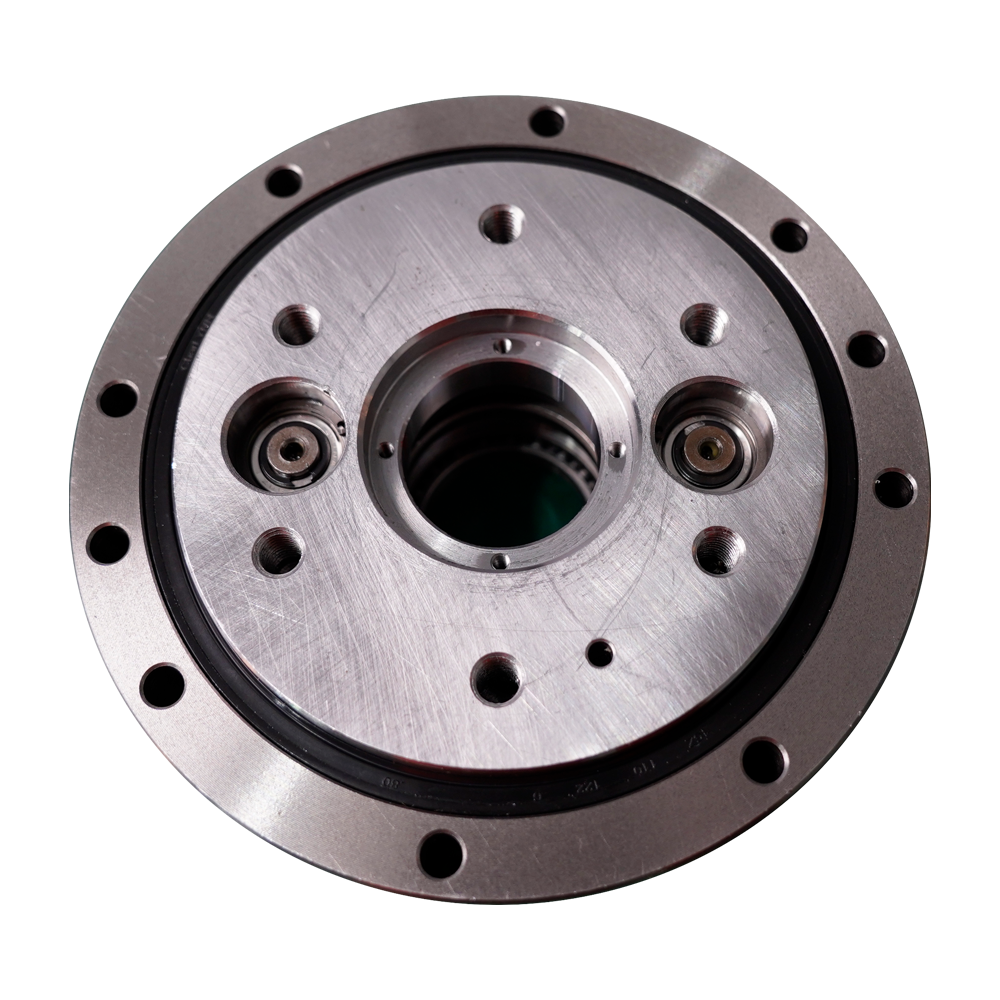

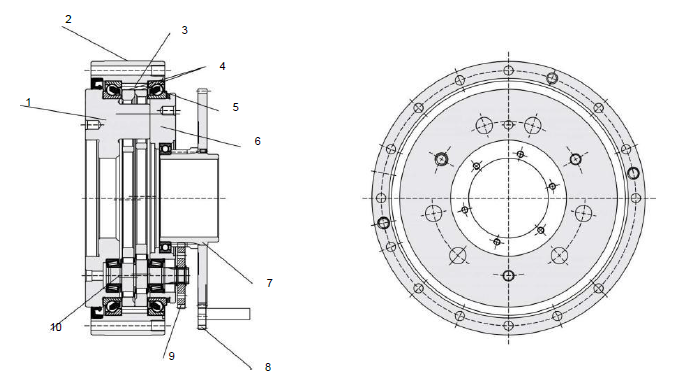

Structure

1. Left planetary Gear carrier 6. Right Planetary gear carrier

2. Pin wheel House 7. Centre Gear

3. Pin 8. Input carrier

4. Cycloid disc 9. Planetary gear

5. Base Bearing 10. Crank Shaft

Technology Parameters

| Model | RV-10C | RV-27C | RV-50C |

| Standard Ratio | 27 | 36.57 | 32.54 |

| Rated Torque (NM) | 98 | 265 | 490 |

| Allowable starting/stopping torque (Nm) | 245 | 662 | 1225 |

| Momentary max.allowable torque(Nm) | 490 | 1323 | 2450 |

| Rated output speed(RPM) | 15 | 15 | 15 |

| Allowable output speed: duty ratio 100% (reference value(rpm) | 80 | 60 | 50 |

| Rated service life(h) | 6000 | 6000 | 6000 |

| Backlash/Lostmotion (arc.min) | 1/1 | 1/1 | 1/1 |

| Torsional rigidity (central value)(Nm/arc.min) | 47 | 147 | 255 |

| Allowable moment (Nm) | 868 | 980 | 1764 |

| Allowable thrust load(N) | 5880 | 8820 | 11760 |

Demension size

| Model | RV-10C | RV-27C | RV-50C |

| A(mm) | 147 | 182 | 22.5 |

| B(mm) | 110h7 | 140h7 | 176h7 |

| C(mm) | 31 | 43 | 57 |

| D(mm) | 49.5 | 57.5 | 68 |

| E(mm) | 26.35±0.6 | 31.35±0.65 | 34.35±0.65 |

Features

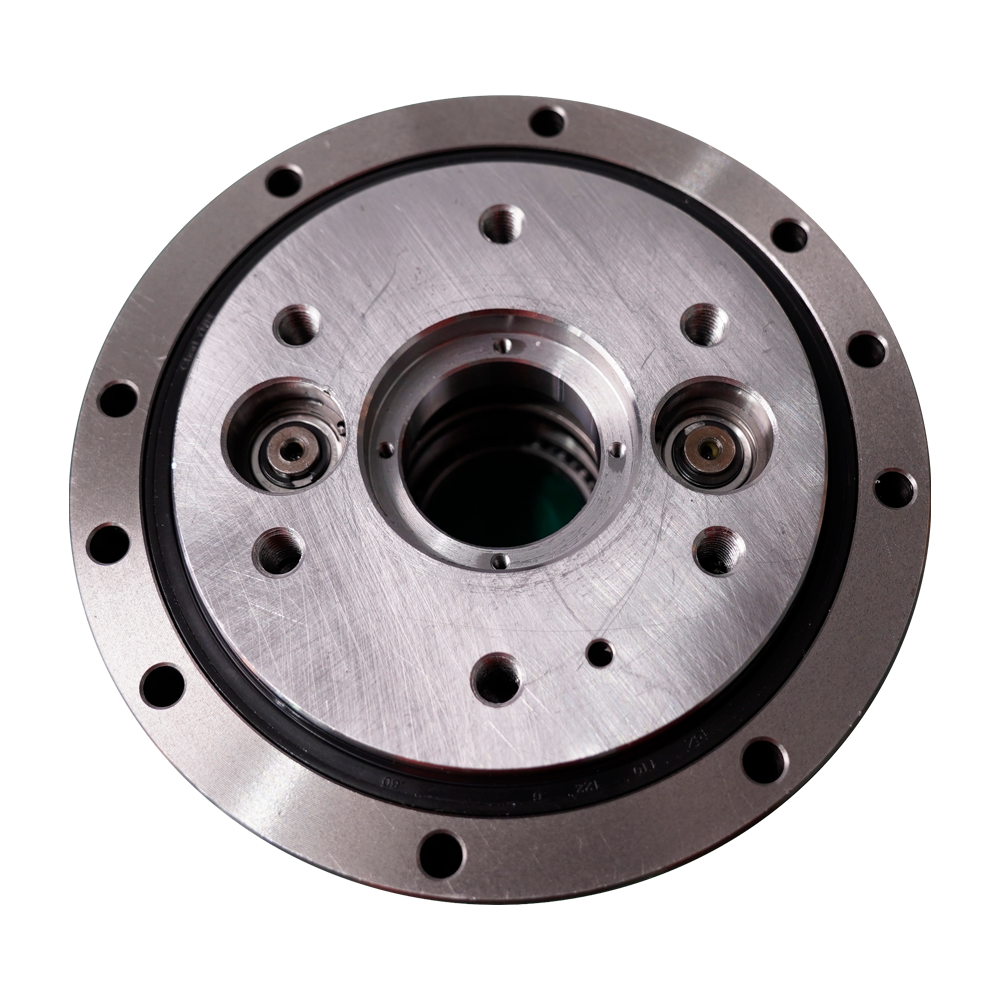

1, Hollow shaft structure

Easy use for Robot cables and lines go through gear

Save a lot spare, Simplification;

2, Ball bearings integrated

It’s good for increasing reliability and reducing cost;

3, Two stage reduction

Good for reducing vibration and inertia

4, Both sides supported

Good for torsional stiffness with less vibration, high load capcity

5, Rolling contact elements

High efficiency, long life and low backlash

6, Pin-Gear structure design

Low backlash with high load capacity

Factory Overview

Daily Maintenance and trouble shooting

| Inspection item | Trouble | Cause | Handling method |

| Noise | Abnormal noise or

Sharp change of sound |

Reducer damaged | Replace reducer |

| Installation problem | Check the installation | ||

| Vibration | Big vibration

Vibration increase |

Reducer damaged | Replace reducer |

| Installation problem | Check installation | ||

| Surface temperature | Surface temperature increase sharply | Oil lack or grease deterioration | Add or replace grease |

| Over rated load or speed | Reduce load or speed to rated value | ||

| bolt |

Bolt loose |

bolt torque not enough |

Tightening bolt as requested |

| oil leakage | Junction surface oil leakage | Object on junction surface | clean ohject on junction surface |

| O ring damaged | Replace O ring | ||

| accuracy | Gap of reducer becomes larger | Gear abrasion | Replace reducer |

CERTIFICATION

Official certified quality assurance

FQA

Q: What should I provide when I choose a gearbox/speed reducer?

A: The best way is to provide the motor drawing with parameters. Our engineer will check and recommend the most suitable gearbox model for your reference.

Or you can also provide the below specification as well:

1) Type, model, and torque.

2) Ratio or output speed

3) Working condition and connection method

4) Quality and installed machine name

5) Input mode and input speed

6) Motor brand model or flange and motor shaft size