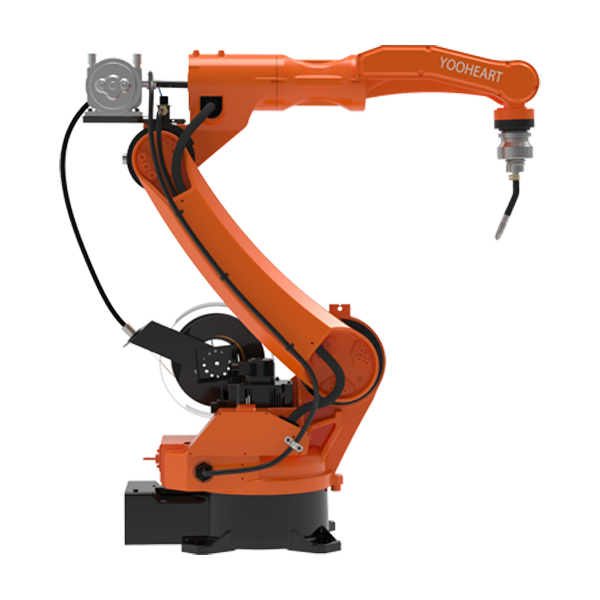

Robot Mig Welding Manual - Tig welding robot with wire feeder – Yunhua

Robot Mig Welding Manual - Tig welding robot with wire feeder – Yunhua Detail:

DELIVERY AND SHIPMENT

Yunhua company can offer customers with different terms of delivery. Customers can choose shipping way by sea or by air according to urgency priority. Yooheart robot packaging cases can meet sea and air freight requirement. We’ll prepare all files like PL, the certificate of origin, invoice and other files. There are a worker whose main job is make sure every robot can be delivered to customers port without a hitch in 40 working days.

After sale service

Yunhua company can offer customers with different terms of delivery. Customers can choose shipping way by sea or by air according to urgency priority. Yooheart robot packaging cases can meet sea and air freight requirement. We’ll prepare all files like PL, the certificate of origin, invoice and other files. There are a worker whose main job is make sure every robot can be delivered to customers port without a hitch in 40 working days.

FQA

Q. How to set power source when using TIG welding?

Your welding machine should be set to DCEN (Direct current electrode negative) also known as straight polarity for any work piece that needs to be welded unless they material is either aluminum or magnesium. High frequency is set to start which is found built in nowadays in inverters. Post flow should be set at least 10 seconds minimum. If A/C is present it is set to default setting that coincides with DCEN. Set the contactor and amperage switches to remote settings. If the material that needs to be welded is aluminum polarity should be set to A/C, A/C balance should be set to about 7 and high frequency supply should be continuous.

Q. How to set shield Gas during TIG welding?

TIG welding uses the inert gas for shielding the welding area from contamination. Thus this inert gas is also stated as shielding gas. At all cases it should be argon and no other inert gas such as neon or xenon etc especially if TIG welding is to be performed. It should be set around 15 cfh. For welding aluminum alone you can make use of a 50/50 combination of argon and helium.

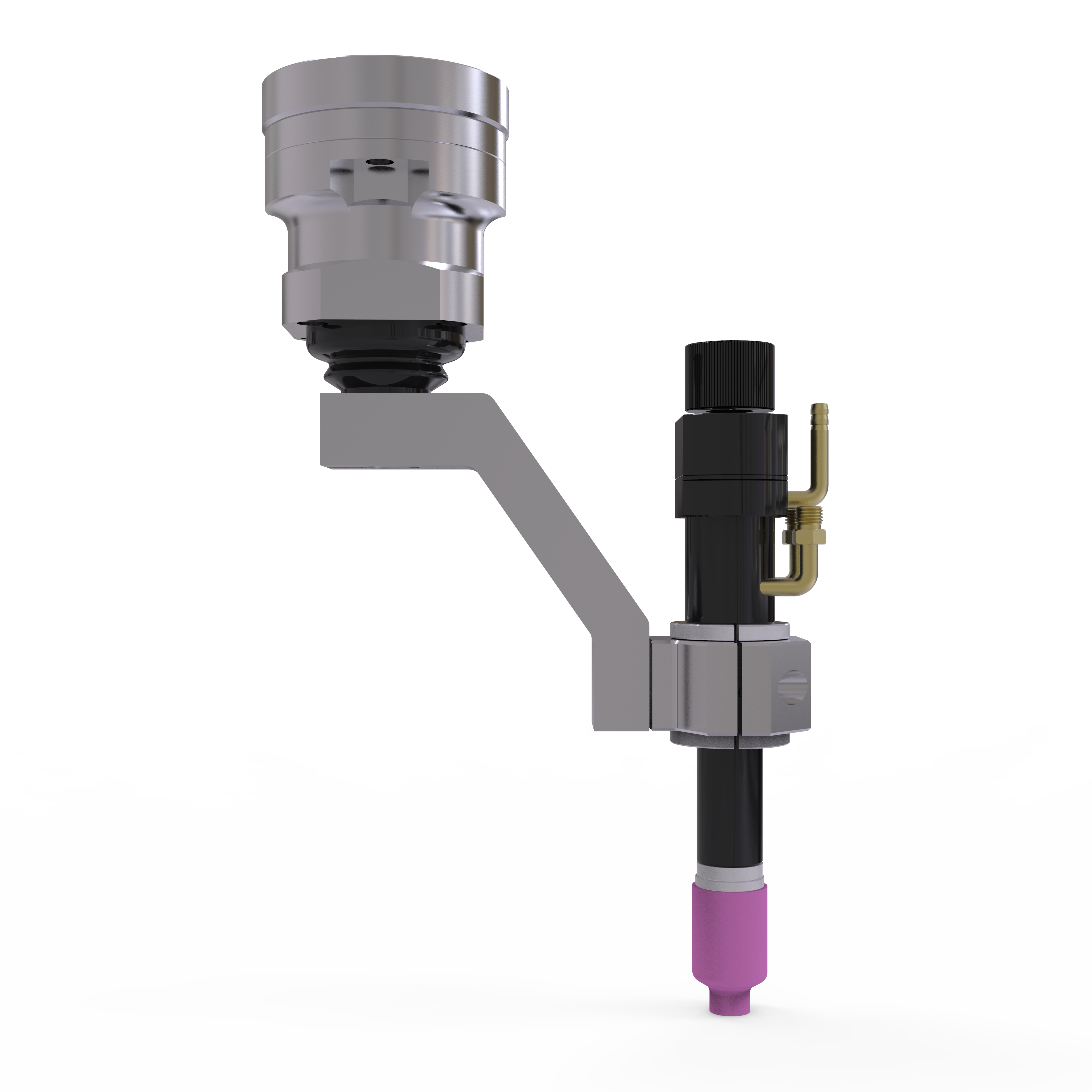

Q. How to choose TIG welding torch?

There are a lot of different kind of torch can be used. But according to the chilling method, you have air cooling TIG torch and water cooling TIG torch. And also, the Ampere will be different, some of them can bear 250AMP, while some of them can only bear 100AMP.

Q. when should I choose water cooling TIG torch and air cooling TIG torch?

You should choose water cooling TIG torch if there are a large quantity of pieces need to weld. But air cooling TIG torch will be a good choice if your pieces is very few.

If you have thick pieces to be weld, water cooling TIG torch is better than air cooling TIG torch.

Q. Is the tungsten electrode used for all applications?

No, for TIG welding it is understood that the electrodes you use to perform TIG welding should be made out of tungsten element. But it’s not means one tungsten electrode can be used for all applications. You should choose different tungsten electrode according to different material.

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our firm. These principles today more than ever form the basis of our success as an internationally active mid-size corporation for Robot Mig Welding Manual - Tig welding robot with wire feeder – Yunhua , The product will supply to all over the world, such as: Montpellier, Saudi Arabia, Zimbabwe, Our aim is to help customers realize their goals. We have been making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, you should do not hesitate to contact us.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!