Robot Mig Welding Definition - Auto parts arc welding robot – Yunhua

Robot Mig Welding Definition - Auto parts arc welding robot – Yunhua Detail:

Welding robot manufaturer

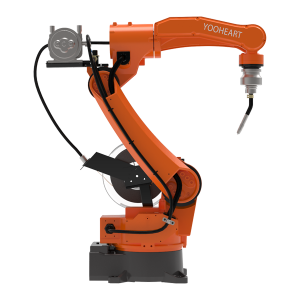

As one of the popular industrial welding robot, it has streamline arm with

min interferenceand max flexibility,

the welding current voltageand wire feeding can be controlled at real-time.

The welding parameters of the welding line can be set directly on the teaching pendant of the robot.

Product Introduction

In today’s technology driven world, robots are playing a major role in manufacturing with about half of those being used for welding applications. Many of those welding robots are being used in the automotive industry. Over the past 30 years automotive welding robots have been busy changing the industry. They have made automotive assembly lines faster while being safer, cost effective, and efficient. These are the main reasons why automotive robots have become paramount in changing the car industry.

we design some of the most versatile and efficient robotic automated welding cells available on the market today. With our robotic welding systems, we provide automotive manufacturers with a reliable solution that can make the thousands of parts they need at a higher, more consistent rate of speed, while maintaining the highest degree of product quality and consistency.

Technology Parameters

| Axis | Payload | Repeatability | Capacity | Environment | Weight | Installation |

| 6 | 6KG | ±0.08mm | 3.7KVA | 0-45℃ 20-80%RH(No forsting) | 170KG | Ground/Hoisting |

| Motion range J1 | J2 | J3 | J4 | J5 | J6 | |

| ±165º | ‘+80º~-150º | ‘+125º~-75º | ±170º | ‘+115º~-140º | ±220º | |

| Max speed J1 | J2 | J3 | J4 | J5 | J6 | |

| 145º/s | 133º/s | 145º/s | 217º/s | 172º/s | 500º/s |

Core Parts

All high Quality products

RV reducer

1. The basic structure of RV reducer is mainly composed of transmission parts worm gear, shaft, bearing, box and accessories.

2. It can be divided into three basic structural parts: box body, worm gear, bearing and shaft combination.

3. RV reducer transmission is stable, vibration, impact and noise is small, its reduction rate is large,

Servo Motor

With more than 100 core independent intellectual property rights, Ruking has more than 100 partners, its sales network covering more than 50 regions around the world. The group adopts the world class R&D system and has ISO9000 and ISO/TS16949 quality system.

Control system

LNC is a top 1 control system brand in Aisa, and owns excellent control technologies of gantry, SCARA, delta and 6-joint robots to meet all kinds of requirements from various industrial applications, such as assembly, testing, package, material handling and processing. We provide full series of standard products and also integration service to satisfy customization demands.

Robot Body

Yooheart Robot will check all incoming materials, and the accuracy requirement is 0.01mm. Only the robot body accessories that meet the requirements will go into the next link for installation.

DETAIL SHOW

All high quality products

HIGH Precision

Fast Action Response

And the level is leading in the country

HIGH Quality

Adopt High Configuration

Power combination

Lightweght body design

Compact

Simple in structure

Easy to maintain

More cost-effective

HIGH Precision

High speed and stability precise path welding solutions

WHY CHOOSE US

performance quality process

Welding Robot

YOO HEART Robot is our best seller, if your work piece is not complicated, this workstation will help you speeding up your productivity. This station includes one 6 axis welding robot, welding power source, one axis positioner and some other useful peripheral equipment. Once you receive this unit, the robot can work after all plugs in. we can also supply simple clamps for you so that you can fit up the work piece stable and fast.

After sale service

Every customer should know YOOHEART robot good before they buy it. Once customers have one YOOHEART robot, their worker will have 3-5 days free training in YOOHEART factory. There will be a wechat group or whatsapp group, our technicians who are responsible for after sale service, electrical, hard ware, software, etc. will be in. If one problem happens twice, our technician will go to customer company to solve the problem.

After sale service

All of Yooheart robot will packed Strictly comply with export packing requirements.

CERTIFICATION

Official certified quality assurance

FQA

Q. How many external axis can Yooheart robot add?

A. At present, Yooheart robot can add 3 more external axis to robot which can collaborate with robot. That is to say, we have standard robot work station with 7 axis, 8 axis and 9 axis.

Q. If we want to add more axis to the robot, is there any choice?

A. Do you know PLC? If you know this, our robot can communicate with PLC, and then give signals to PLC to control external axis. In this way, you can add 10 or more external axis. The only shortage of this way is that the external axis can not collaborate with robot.

Q. How PLC communicate with robot?

A. We have i/O board in the control cabinet, there are 20 output port and 20input port, PLC will connect I/O board and receive signals from robot.

Q. Can we add more I/o port?

A. For simply weld application, these I/O port is enough, if you need more, we have I/O expanding board. You can add another 20 input and output.

Q. What kind of PLC do you use?

A. Now we can connect Mitsubishi and Siemens and also some other brands.

Product detail pictures:

Related Product Guide:

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for Robot Mig Welding Definition - Auto parts arc welding robot – Yunhua , The product will supply to all over the world, such as: Vietnam, Berlin, Macedonia, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.