Robot Cutting System - One Axis rotator – Yunhua

Robot Cutting System - One Axis rotator – Yunhua Detail:

Introduction

The single axis head-tail positioner is a positioner whose head frame drives to rotate, and tail frame follows to rotate. This positioner is designed for long work piece, the work table between the head and tail can rotate to place work piece at the best welding position. This model include: basement, head frame, tail frame, working table, servo motor, RV reducer, etc.

Technology data:

| Positioner mode | Voltage | Insulation grade | Working table | Weight | Min Payload |

| HY4030A-250A | 3 phase380V±10%,50/60HZ | F | 1800×800mm(tailor made support) | 450kg | 300kg |

Delivery and shipment

Yunhua company can offer customers with different terms of delivery. Customers can choose shipping way by sea or by air according to urgency priority. YOO HEART packaging cases can meet sea and air freight requirement. We’ll prepare all files like PL, the certificate of origin, invoice and other files. There is a worker whose main job is make sure every robot can be delivered to customers port without a hitch in 40 working days.

After sale service

Every customer should know YOO HEART robot good before they buy it. Once customers have one YOO HEART robot, their worker will have 3-5 days free training in Yunhua factory. There will be a Wechat group or WhatsApp group, our technicians who are responsible for after sale service, electrical, hard ware, software, etc, will be in. If one problem happens twice, our technician will go to customer company to solve the problem.

FQA

Q1.Whether is the working table contained in the standard positioner?

A.Yes, it is. The standard size is 1800mm×800mm.

Q2. Do you have larger working table?

A.We can tailor made the working table, if you need larger size, you can write your requirement into contract.

Q3. What kind of reducer do you use?

A.RV reducer.

Q4. How many motors do the positioner have?

A.One servo motor included.

Q5. What’s the term of packaging for positioner?

A.Normally wooden, it is strong packaged. If you do not use our package and use your own, please let us know before package.

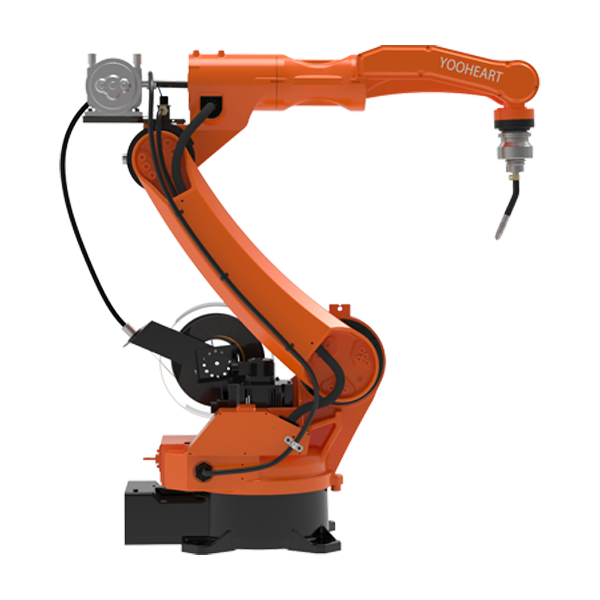

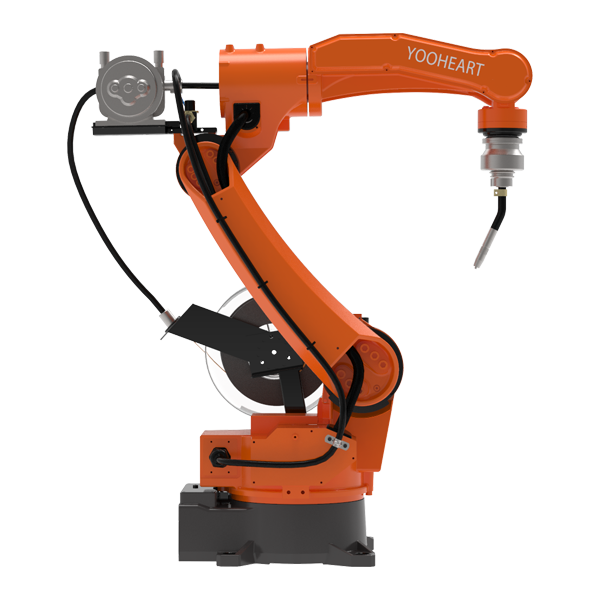

Product detail pictures:

Related Product Guide:

We regularly perform our spirit of ''Innovation bringing progress, Highly-quality making certain subsistence, Administration marketing benefit, Credit score attracting customers for Robot Cutting System - One Axis rotator – Yunhua , The product will supply to all over the world, such as: Cologne, Italy, Birmingham, Our solutions have national accreditation requirements for qualified, good quality items, affordable value, was welcomed by individuals all over the world. Our goods will continue to improve inside the order and appear forward to cooperation with you, Really should any of those items be of interest to you, please letus know. We will be satisfied to provide you a quotation up on receipt of the detailed needs.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.