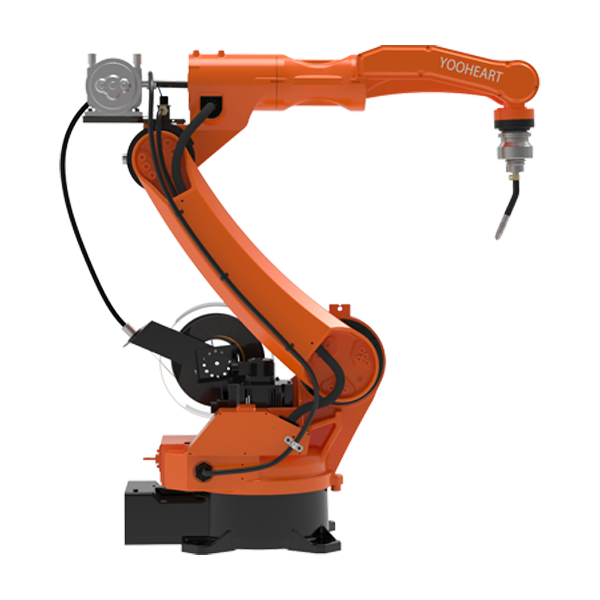

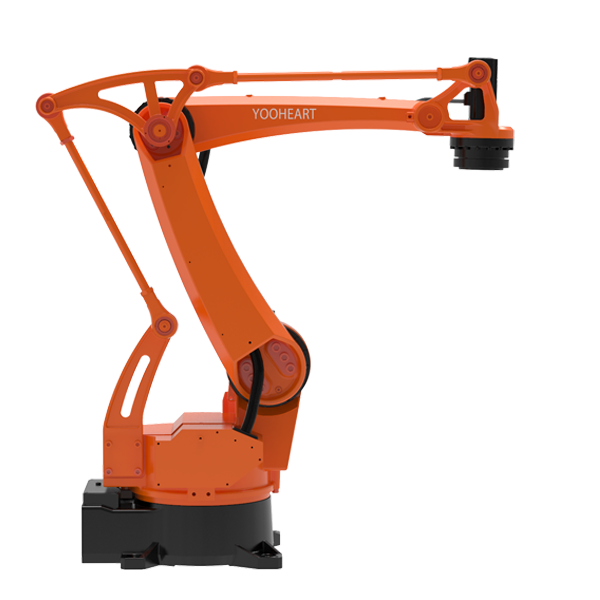

Robot Assembly Cycle Time - Palletizing robot – Yunhua

Robot Assembly Cycle Time - Palletizing robot – Yunhua Detail:

DELIVERY AND SHIPMENT

Yunhua company can offer customers with different terms of delivery. Customers can choose shipping way by sea or by air according to urgency priority. YOOHEART packaging cases can meet sea and air freight requirement. We’ll prepare all files like PL, the certificate of origin, invoice and other files. There is a worker whose main job is make sure every robot can be delivered to customers port without a hitch in 40 working days.

After sale service

Every customer should know YOOHEART robot good before they buy it. Once customers have one YOO HEART robot, their worker will have 3-5 days free training in Yunhua factory. There will be a Wechat group or WhatsApp group, our technicians who are responsible for after sale service, electrical, hard ware, software, etc, will be in. If one problem happens twice, our technician will go to customer company to solve the problem.

FQA

Q1.When is robotic palletizing cost effective?

A. take China for example, now Employees salary is very high, especially labor force. If you use YOO HEART robot and one technician who knows robot good, you can reduce 3-4 human cost.

Q2.What types of products can be palletized by robot

A. a lot products which need palletized or depalletized can use Robot.

Q3.What’s the biggest payload of Palletizing robot

A. At present, 165kg is the biggest payload, but from May 2021 on, there will be 250kg for palletizing and depalletizing.

Q4.Can a robotic palletizer run more then one product at a time

A. two questions take into consideration, 1, total weight, together with clamps weight should less than robot rated payload. 2, the clamps is bigger enough for grabbing more product.

Q5.what’s your advantages compared with other Chinese brand.

A. well, YOOHEART robot is the first Chinese industrial robot brand, we start manufacturing robot from 2013, and totally sold nearly 15000 unit all over the world. As others brand, CRP, JZJ, JHY, QJAR, they are just few years. We use our own RV reducer, and all parts use Chinese brand, this is why we can reduce robot price and let all customer use good quality robot with low cost.

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a purchaser position of principle, allowing for greater top quality, decrease processing costs, price ranges are much more reasonable, won the new and aged prospects the support and affirmation for Robot Assembly Cycle Time - Palletizing robot – Yunhua , The product will supply to all over the world, such as: Australia, Ireland, Mexico, Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, please click the button to acquire additional nformation.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.