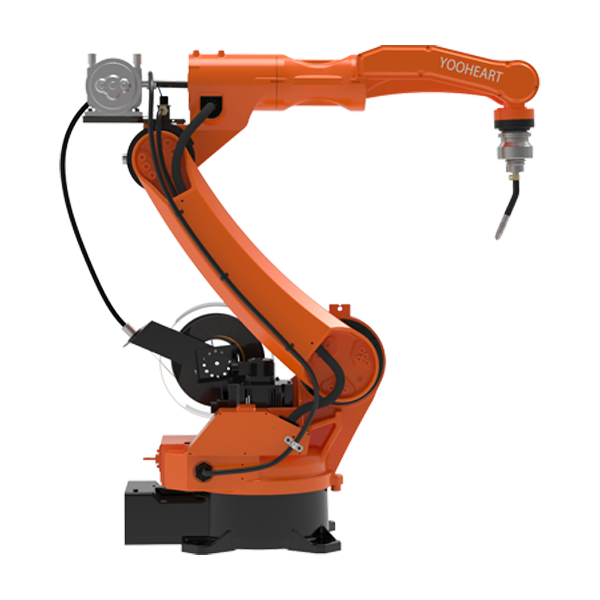

Assembly Line Robot Arm - Loading and unloading robot – Yunhua

Assembly Line Robot Arm - Loading and unloading robot – Yunhua Detail:

DELIVERY AND SHIPMENT

Yunhua company can offer customers with different terms of delivery. Customers can choose shipping way by sea or by air according to urgency priority. YOOHEART packaging cases can meet sea and air freight requirement. We’ll prepare all files like PL, the certificate of origin, invoice and other files. There is a worker whose main job is make sure every robot can be delivered to customers port without a hitch in 40 working days.

After sale service

Every customer should know YOOHEART robot good before they buy it. Once customers have one YOOHEART robot, their worker will have 3-5 days free training in Yunhua factory. There will be a Wechat group or WhatsApp group, our technicians who are responsible for after sale service, electrical, hard ware, software, etc, will be in. If one problem happens twice, our technician will go to customer company to solve the problem.

FQA

Q1.Is this safe for workers?

A. sure, one of the advantages of using robot for pick and place is protect workers from injuries. One worker can handle 5~6 units CNC machine.

Q2.What kind of product can use loading and unloading robot?

A. Each robotic machine loader can be fitted with proper end-of-arm-tooling that is compatible with your machine and product. They are extremely accurate and also have the dexterity to handle the part with care.

Q3.Only one end of arm tools can be used for loading and unloading robot?

A. Industrial robot arm can modify the program and the gripper clamp, rapid changes in the intelligent warehousing, debugging speed, eliminating the need for employees but also for the training time, can be quickly put into production.

Q4.is there any other merit of loading and unloading robot?

A. Improve the quality of the workpiece Appearances: robot automated production lines, from feeding, clamping, cutting entirely by robots, to reduce intermediate links, part quality is greatly improved, especially more beautiful surface.

Q5.Can you supply full solutions for loading and unloading robot?

A. sure, we can do that together with our dealer.

Product detail pictures:

Related Product Guide:

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for Assembly Line Robot Arm - Loading and unloading robot – Yunhua , The product will supply to all over the world, such as: Mauritania, Kuwait, Hongkong, We firmly think that we have the full capability to present you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!