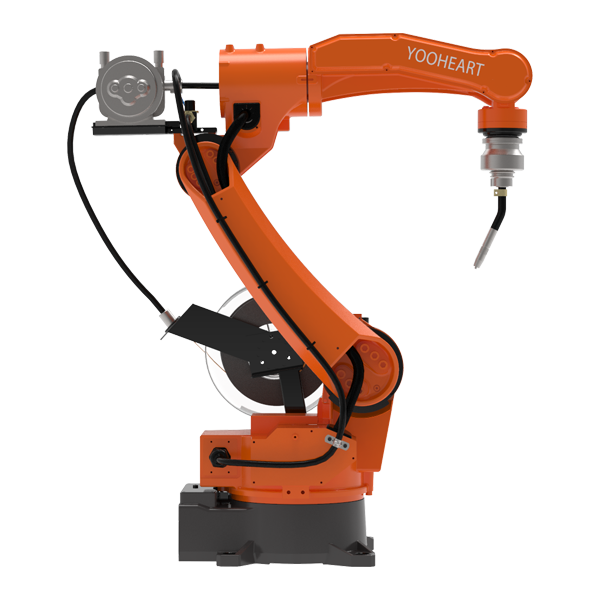

What Is A Welding Robot - 7 Axis Robotic Arc Welding Workstation – Yunhua

What Is A Welding Robot - 7 Axis Robotic Arc Welding Workstation – Yunhua Detail:

DELIVERY AND SHIPMENT

YOO HEART company can offer customers with different terms of delivery. Customers can choose shipping way by sea or by air according to urgency priority. YOO HEART robot packaging cases can meet sea and air freight requirement. We’ll prepare all files like PL, the certificate of origin, invoice and other files. There is a worker whose main job is make sure every robot can be delivered to customer port without a hitch in 20 working days.

After sale service

Every customer should know YOOHEART robot good before they buy it. Once customers have one YOOHEART robot, their worker will have 3-5 days free training in YOOHEART factory. There will be a wechat group or whatsapp group, our technicians who are responsible for after sale service, electrical, hard ware, software, etc. will be in. If one problem happens twice, our technician will go to customer company to solve the problem.

FQA

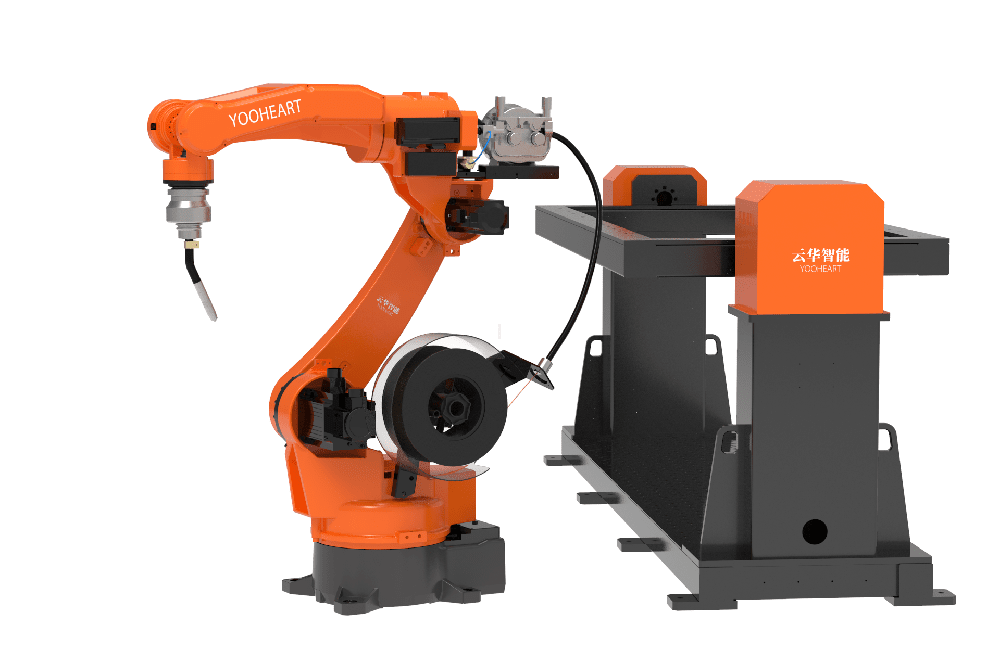

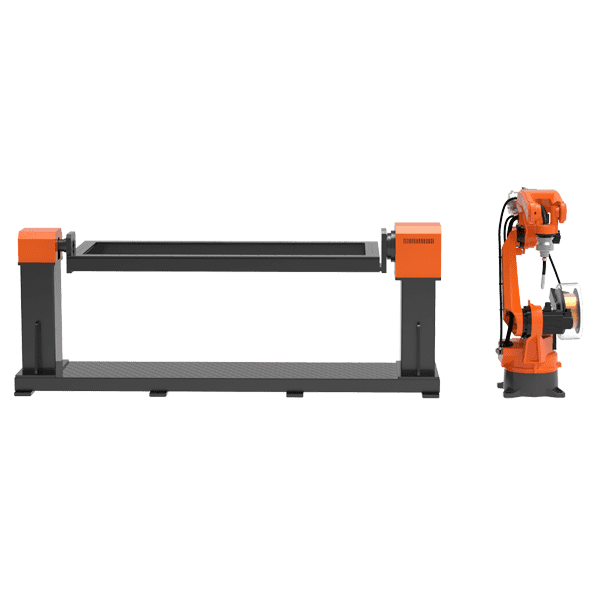

Q1.How many external axis can YOO HEART robot add?

A.At present, YOO HEART robot can add 3 more external axis to robot which can collaborate with robot. That is to say, we have standard robot work station with 7 axis, 8 axis and 9 axis.

Q2. If we want to add more axis to the robot, is there any choice?

A. Do you know PLC? If you know this, our robot can communicate with PLC, and then give signals to PLC to control external axis. In this way, you can add 10 or more external axis. The only shortage of this way is that the external axis can’t collaborate with robot.

Q3. How PLC communicate with robot?

A. We have i/O board in the control cabinet, there are 22 output port and 22 input port, PLC will connect I/O board and receive signals from robot.

Q4. Can we add more I/o port?

A. For simply weld application, these I/O port is enough, if you need more, we have I/O expanding board. You can add another 22 input and output.

Q5. What kind of PLC do you use?

A. Now we can connect Mitsubishi and Siemens and also some other brands.

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for What Is A Welding Robot - 7 Axis Robotic Arc Welding Workstation – Yunhua , The product will supply to all over the world, such as: French, Naples, Sydney, Our monthly output is more than 5000pcs. We have set up a strict quality control system. Please feel free to contact us for further information. We hope that we can establish long-term business relationships with you and carry out business on a mutually beneficial basis. We are and will be always trying our best to serve you.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!