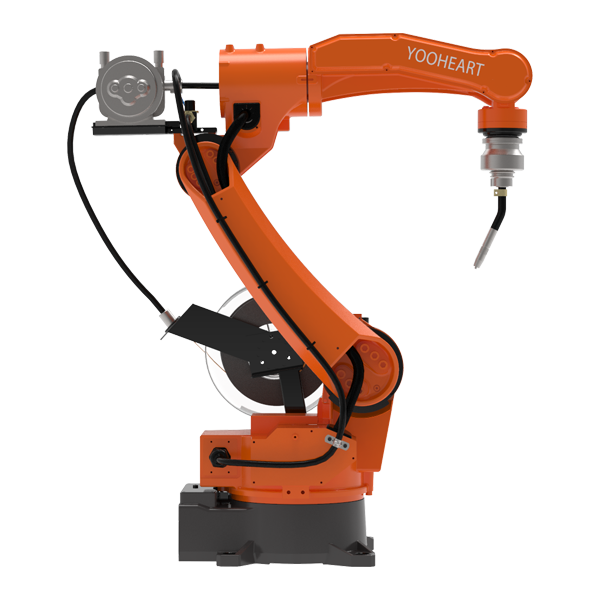

Pallet Handling Robot - stamping robot HY1005A-085 – Yunhua

Pallet Handling Robot - stamping robot HY1005A-085 – Yunhua Detail:

Introduction

YOO HEART stamping robot is designed for stamping manufacturers, these company concerned about employee safety, an increasing skills gap and pressure to meet higher throughput demand.

HY1005A-085 is the most compact stamping robot which can be moved by a single man.

Technology data:

| Axis | Max Payload | Repeatibility | Capacity | Environment | Weight | Installation | IP level |

| 6 | 5KG | ±0.03 | 1.6kva | 0-45℃No humidity | 60kg | Ground/wall/ceiling | IP65 |

| Motion range J1 | J2 | J3 | J4 | J5 | J6 | ||

| ±170° | +60°~-150° | +205°~-50° | ±130° | ±125° | ±360° | ||

| Max Speed J1 | J2 | J3 | J4 | J5 | J6 | ||

| 145°/S | 133°/S | 140°/S | 172°/S | 172°?S | 210°/S | ||

Working Range

Delivery and shipment

Yunhua company can offer customers with different terms of delivery. Customers can choose shipping way by sea or by air according to urgency priority. YOO HEART packaging cases can meet sea and air freight requirement. We’ll prepare all files like PL, the certificate of origin, invoice and other files. There is a worker whose main job is make sure every robot can be delivered to customers port without a hitch in 40 working days.

After sale service

Every customer should know YOO HEART robot good before they buy it. Once customers have one YOO HEART robot, their worker will have 3-5 days free training in Yunhua factory. There will be a Wechat group or WhatsApp group, our technicians who are responsible for after sale service, electrical, hard ware, software, etc, will be in. If one problem happens twice, our technician will go to customer company to solve the problem.

FQA

Q1. Is there any application videos can be shown?

A. you have two way to get this, 1, you can contact us and request for these videos, 2, visit our Youtube channel, there are so many good applications

https://www.youtube.com/channel/UCX7MAzaUbLjOJJVZqaaj6YQ

Q2. Should I use 4 axis Robot for stamping?

A. Not exactly, that should according to really situation, if the application is simple, 4 axis robot is good. But if the application a little complicated, you maybe use 6 axis robot.

Q3. How many model do you have for Stamping functions

A, we have models: 085,098,143,140,180,200, payload from 3kg to 165kg can be used for stamping.

Q4. which is the smallest model?

A, if you just want to test our robot function, you can choose HY1005A-085, whose payload is 5kg and reach is 850mm

Q5. How can I connect robot and stamping machine?

A. Our robot can share signals through I/O port, if your stamping machine can receive and send signal, then it can communicate with robot.

Product detail pictures:

Related Product Guide:

We hold strengthening and perfecting our items and repair. At the same time, we get the job done actively to do research and progress for Pallet Handling Robot - stamping robot HY1005A-085 – Yunhua , The product will supply to all over the world, such as: New Delhi, Los Angeles, Ecuador, Our company will continue to adhere to the " superior quality, reputable, the user first " principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.