Factory Free sample Robot Assembly Cell - Palletizing robot And Depalletizing robot – Yunhua

Factory Free sample Robot Assembly Cell - Palletizing robot And Depalletizing robot – Yunhua Detail:

Introduction

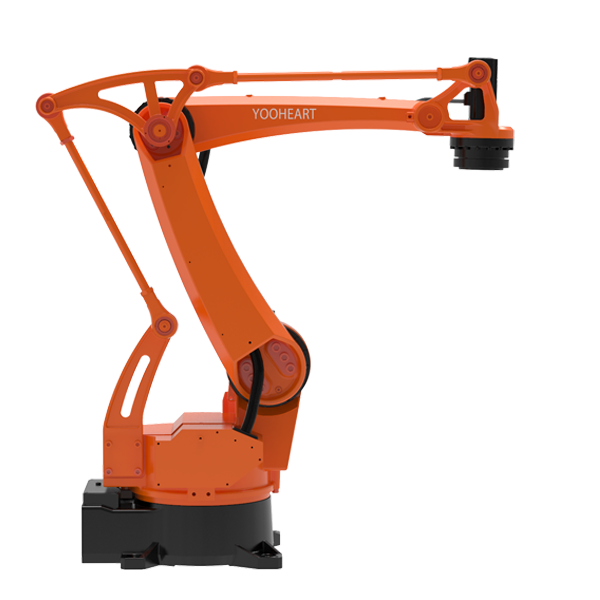

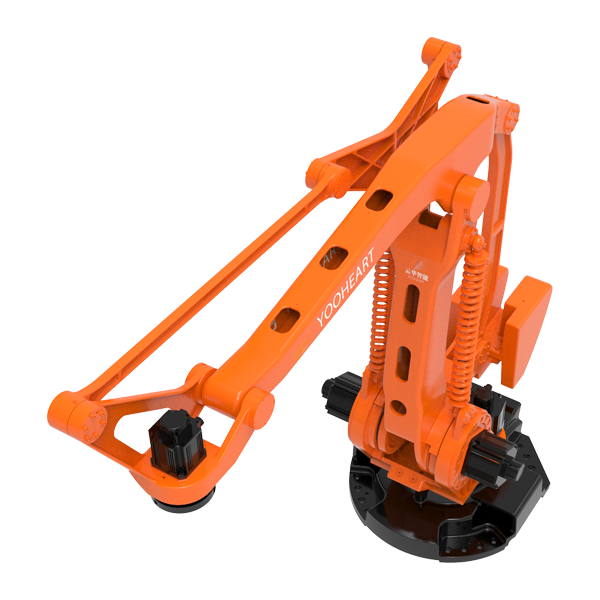

HY1165B-315 is a 4 axis robot mainly used in palletizing. it is a machine device used for the automatic execution of work, which can automatically stack objects into containers on pallets under a pre-arranged program, it can stack in multiple layers, and then push out to facilitate the transportation of forklifts to warehouses for storage. Its purpose is to assist or replace human palletizing.

Users can operate it by a simple system to palletize goods, in doing so, it not only helps users to save warehouse space and human resources, but also improve the palletizing efficiency and make goods stack more neat.

Rice handling application with Rice Stacking application Cartons Palletizing from convey

big payload

Technology data:

| xis | MAWL | Positional repeatability | Powercapacity | Operating environment | Sheer weight | Installment |

| 4 | 165 KG | ±2mm | 10KVA | 0-45℃ | 1500KG | ground |

| Motion range | J1 | J2 | J3 | J4 | IP grade | IP54/IP65(waist) |

| ±180° | +5°~130° | +15°~-60° | ±360° | |||

| Maximum speed | 70°/s | 82°/s | 82°/s | 200°/s |

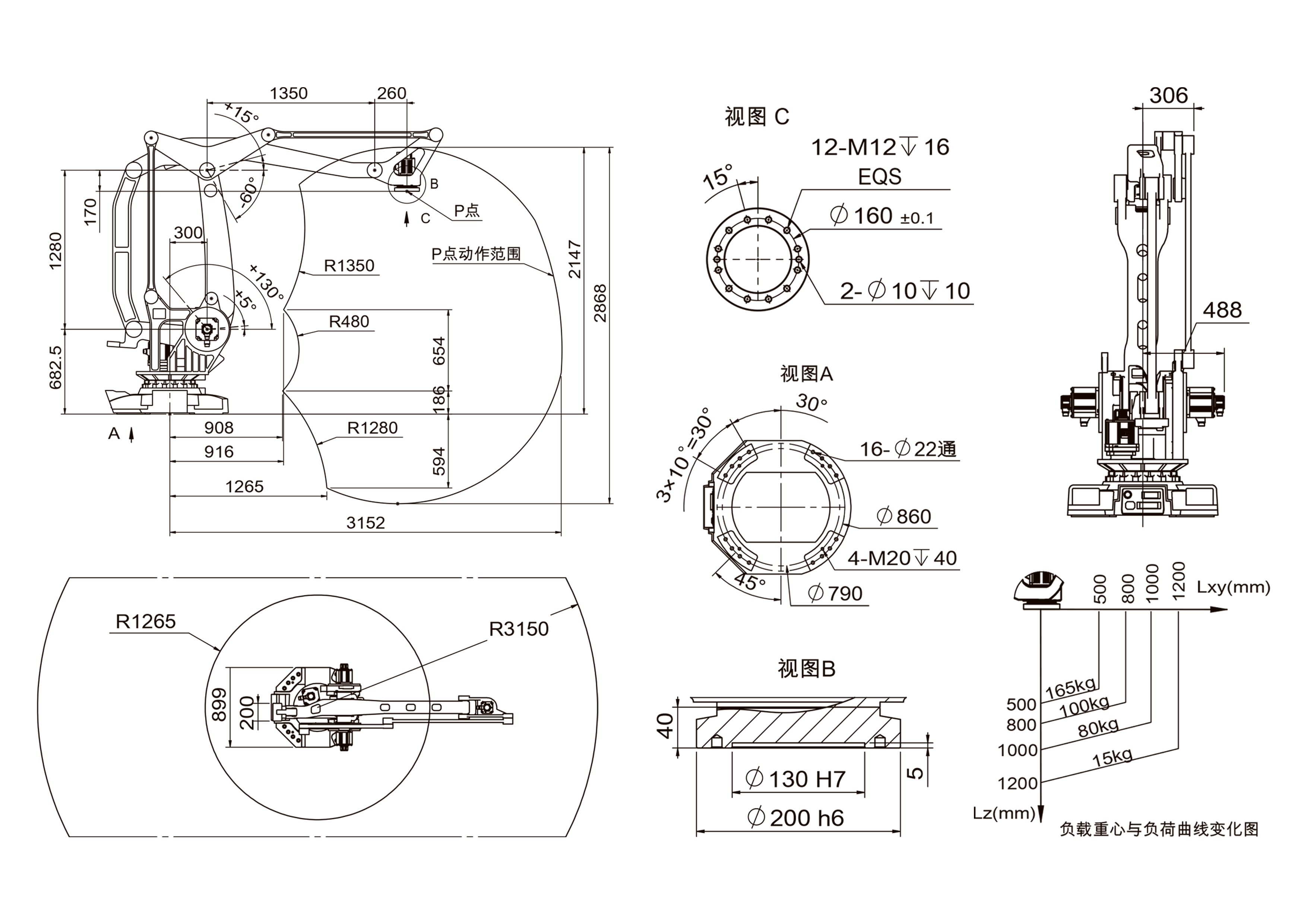

Working Range

Delivery and shipment

Yunhua company can offer customers with different terms of delivery. Customers can choose shipping way by sea or by air according to urgency priority. YOOHEART packaging cases can meet sea and air freight requirement. We’ll prepare all files like PL, the certificate of origin, invoice and other files. There is a worker whose main job is make sure every robot can be delivered to customers port without a hitch in 40 working days.

After sale service

Every customer should know YOO HEART robot good before they buy it. Once customers have one YOO HEART robot, their worker will have 3-5 days free training in Yunhua factory. There will be a Wechat group or WhatsApp group, our technicians who are responsible for after sale service, electrical, hard ware, software, etc, will be in. If one problem happens twice, our technician will go to customer company to solve the problem.

FQA

Q1.How does the cost of a robotic palletizer compare with other alternatives?

A.A robotic palletizer is more expensive than a single product hard palletizing system but it is less expensive than a large dedicated palletizer with multiple infeeds. Robotic palletizing can range from $10K in its simplest form to $30K+ for robot body.

Q2.What types of End-of-Arm-Tooling (EOAT) are used for palletizing?

A.There are a number of EOAT options available each with their own specific uses. Vacuum cups or pads are generally used for closed top cases and pails. A scoop tool or a combo scoop & clamp tool is generally used for open top cases or trays. A bag tool with lifting fingers & a tamp is generally used for large bags in the 20-100 # range. Odd shaped parts are generally picked up with a clamp tool.

Q3.What is a palletizing robot?

A.By automating your shop with a palletizing robot, you can increase the consistency of your loading and unloading processes.

Q4.what do you think YOO HEART when talking with Japan and Europe brand robot?

A.we still have a quite long way, we must see this. And our aim customer is small and medium factory who can’t afford big money for these famous brands, Like ABB, Funac, Kuka, Yaskawa, OTC.

Q5.Where can I practice your robot control system?

A.Which country are you in? you can come to our factory for deeply free training. Or you can ask our dealers in your country for help.

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can guarantee our combined price competiveness and quality advantageous at the same time for Factory Free sample Robot Assembly Cell - Palletizing robot And Depalletizing robot – Yunhua , The product will supply to all over the world, such as: Czech Republic, Ecuador, Algeria, Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!