Reducer, that is, reduce the speed of movement, increase torque, improve accuracy of a mechanical device, widely used in high load, high precision, high speed of precision processing industry.

After the establishment of Yunhua intelligent, has been committed to the R & D of RV reducer.Because we know that “can not overcome the RV reducer, then the road of industrial robots will not go down”, so in the RV reducer this core parts can be said to spend all their thoughts,Invested a lot of time, manpower and huge scientific research funds independently developed 6 RV reducer YH10C, YH50C, YH20E, YH40E, YH80E, YH110E.

An RV reducer needs to go through dozens of processes, the flow of assembly, testing, quality inspection and other departments for production, testing before it can be put into use.

● Incoming material inspection

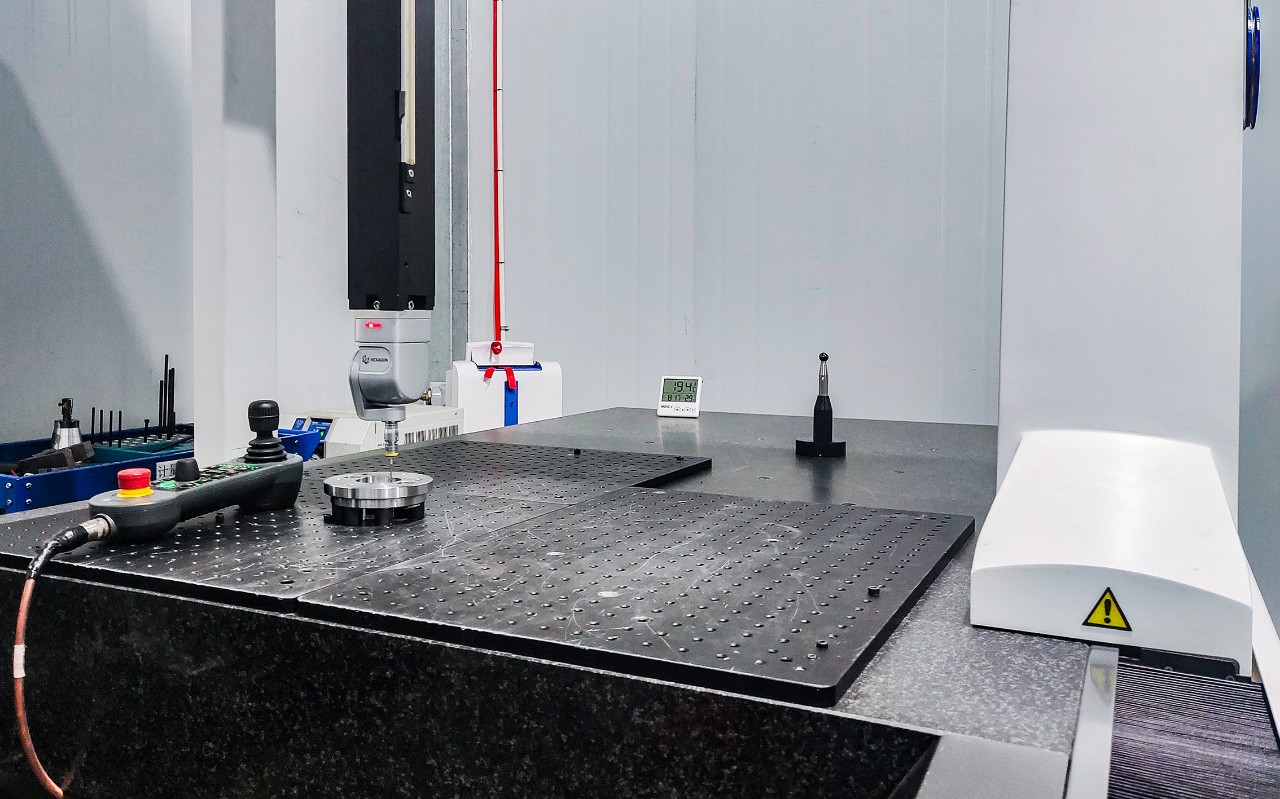

Here is the first stop for the processing of gear reducer parts and materials, where all materials must be inspected first.The inspection personnel need to check whether the appearance of the casting is sand holes, cracks and defects, and whether it meets the standard, etc. In addition, they also need to operate the three-coordinate machine to check whether the size of the casting is consistent with the data marked on the drawing.’

● Processing (take the planetary frame as an example)

Rough processing: the casting passed by the external inspection center needs to be simply processed. The output disc and gland are roughened and refined by a professional machine and assembled into a planetary frame. After drilling and rehinging the positioning pin holes on the planetary frame, the positioning pin is inserted.

Semi-finishing: because of the large error of the surface allowance after rough machining, in order to ensure that the planetary frame has a stable machining allowance in finishing machining, the planetary frame needs to process its bearing position on the semi-finishing vehicle.

Finishing: The planetary frame is put into the machining center in the finishing area, and its bearing hole is fine boring and grinding in a more stable and efficient way, so as to improve its manufacturing accuracy and improve the performance and life of the robot.

A reducer has more than ten parts, each part of the processing method, processing procedures are not the same, but each part needs to be repeated grinding, boring, honing processing, it can be imagined that the RV reducer research and development and production of high difficulty.

RV test

After a series of processing, all parts have a qualitative change, all parts into the RV testing room, technical personnel operation using three coordinate machine two times to check its dimensional accuracy and input all data into the database, at present Yunhua intelligent RV reducer bearing coaxiality is controlled within 0.005um, very fine.

● Deburring, cleaning, demagnetization

Deburring and cleaning make parts smooth and reduce resistance during assembly.Demagnetization is to remove the magnetism on the parts so that they will not be absorbed by dust.

● Semi-finished products warehouse

All processed and tested qualified parts will be put into the semi-finished products warehouse, and special parts need to be marked and then stored in the warehouse for assembly, and part of the discarded parts will be put into the waste area for subsequent recycling.

● Finished product assembly

RV reducer assembly is also very important, may one not careful will cause reducer, quality, safety problems in the workshop, the assembly personnel will planet carrier, cycloid tooth shell plate, needle, etc all kinds of parts assembled into complete reducer, process, each assembly workers in the assembly is very careful, when repeatedly check, confirm and correct assembly and then on to the next step.

● Finished product inspection

This is the last step of reducer production, and RV reducer as the core parts of the robot, the pros and disadvantages of reducer will directly affect the performance, quality and life of the robot, all quality problems must not happen.In the quality inspection area, technicians will conduct a series of tests such as start-up torque, return error and efficiency test on the assembled reducer through high-end testing equipment.

Low finished-parts storage

Those that pass the machine test will be stored in the finished product warehouse for subsequent robot assembly.

Nowadays the RV reducer technology no longer subject to foreign countries, so as to save money, support for scientific research personnel to develop better products, Muscovite, mica muscovitum intelligence researchers have not afraid of hardship, careful efficient production personnel, whether in production, research and development or cooperation, we follow up project will be thousands of risks, in addition to the refugees, sleek, thriving!

Post time: Dec-22-2021