The application of welding robots should strictly control the preparation quality of parts and improve the assembly accuracy of weldments. The surface quality, groove size and assembly accuracy of the parts will affect the welding seam tracking effect. The quality of parts preparation and the accuracy of weldment assembly can be improved from the following aspects.

(1) Compile a special welding process for welding robots, and make strict process regulations on the size of parts, weld grooves, and assembly dimensions. Generally, the tolerance of parts and groove dimensions is controlled within ±0.8mm, and the assembly dimension error is controlled within ±1.5mm. The probability of welding defects such as pores and undercuts in the weld can be greatly reduced.

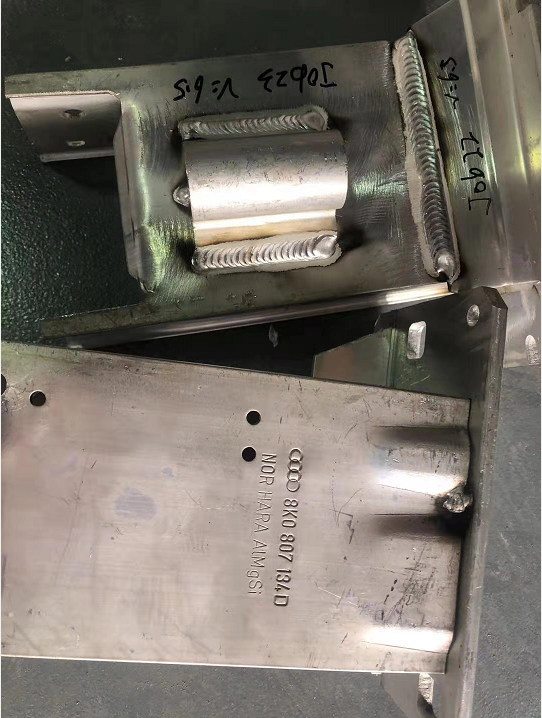

(2) Use high-precision assembly tooling to improve the assembly accuracy of weldments.

(3) Welding seams should be cleaned, free of oil, rust, welding slag, cutting slag, etc., and solderable primers are allowed. Otherwise, it will affect the success rate of arc ignition. Tack welding is changed from electrode welding to gas shielded welding. At the same time, the spot welding parts are polished to avoid residual slag crusts or pores due to tack welding, so as to avoid arc instability and even spatter.

Post time: Sep-11-2021