Non-woven fabric has the advantages of light and soft, non-toxic and antibacterial, waterproof and heat preservation, good air permeability and so on. The pollution degree of waste to the environment is only 10% of the plastic bag, and it is internationally recognized as an environmental protection product to protect the earth ecology. At the same time, non-woven products short process, production speed, low price, so it is widely used in agriculture, industry, home decoration, clothing, especially medical, health and other fields, have a very big impact and effect.

I. Sore point on the program

After the non-woven fabric is produced, it needs to be rolled into a cylinder, then transported to the packing area, fixed with a film, and then transported to the warehouse for storage and transportation.

Non-woven fabric surface smooth, fragile, manual handling, palletization is likely to cause damage to the product.At the same time, the weight of non-woven fabric rolled into a cylinder is about 30~100kg, and the repeated handling and stacking operation of production line employees all day is easy to cause damage to their body, and the production efficiency will also be affected.In order to ensure product quality and production efficiency, the requirements of non-woven fabric handling and palletizing work have increased greatly, requiring a faster, more efficient and safer way to complete the handling and palletizing work.

The customer decided to use Yunhua intelligent robot to replace manual handling and stacking of non-woven fabric, to ensure the quality and integrity of products, to achieve “production, transportation, rolling, coding, storage” five steps of smooth and fast operation, so as to improve production efficiency, ensure staff safety, release staff energy.

II. Solution

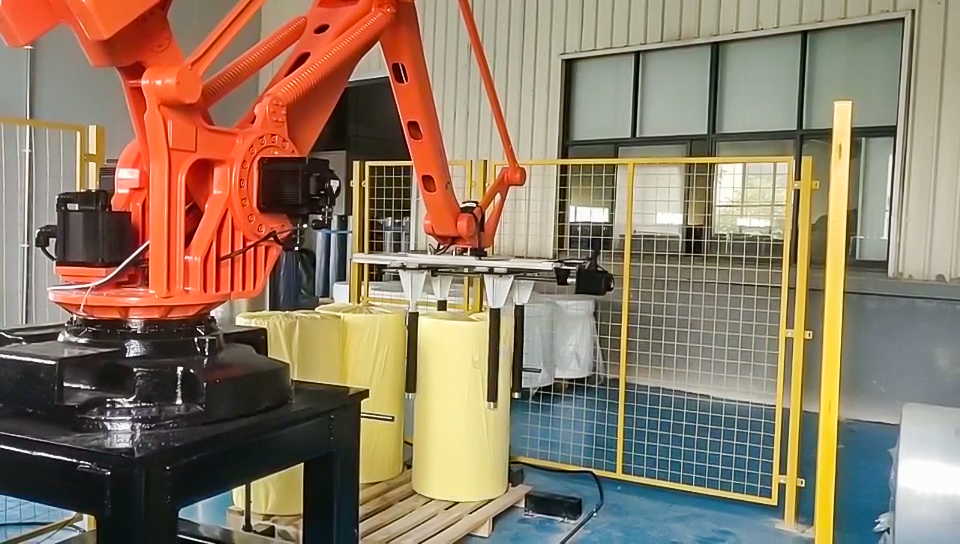

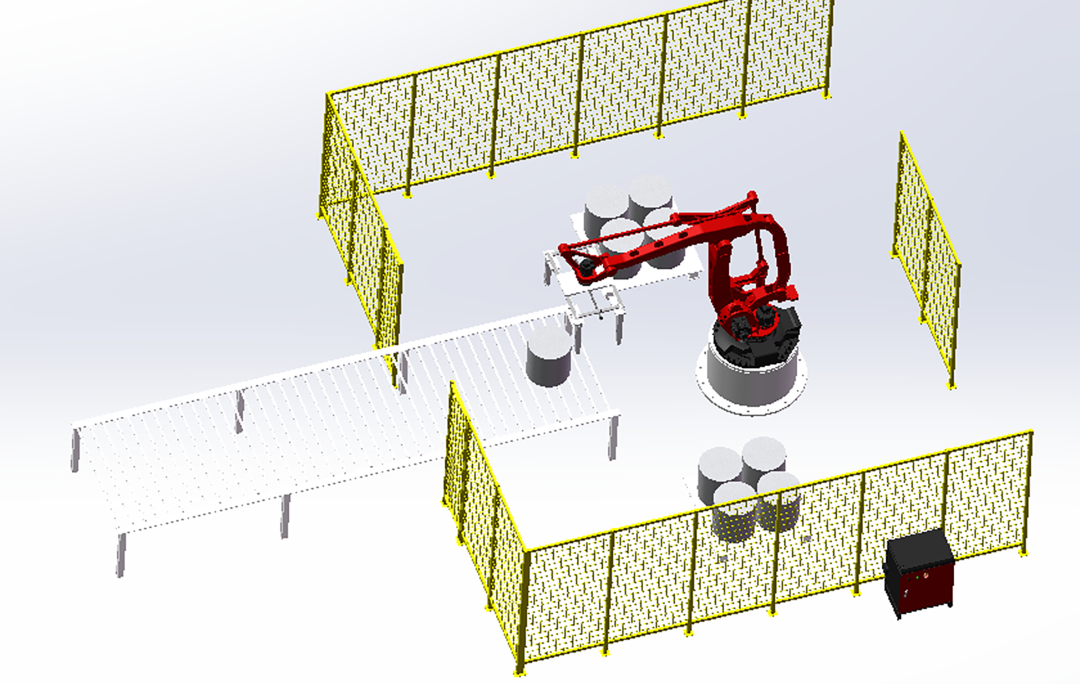

According to the requirements of the existing production line and production environment conditions, we provide our clients with a handling robot workstation HY1165B – 315, including in addition to the robot body, base, control cabinet, jigs and other accessories, also equipped with the product and pour rack, and pallet, safety fence and grating safety protective equipment, such as repeated positioning precision can be up to + / – 2 mm, safe accurate grab,Efficient and stable handling, palletizing, perfect to meet customer’s non-woven fabric handling, palletizing needs.

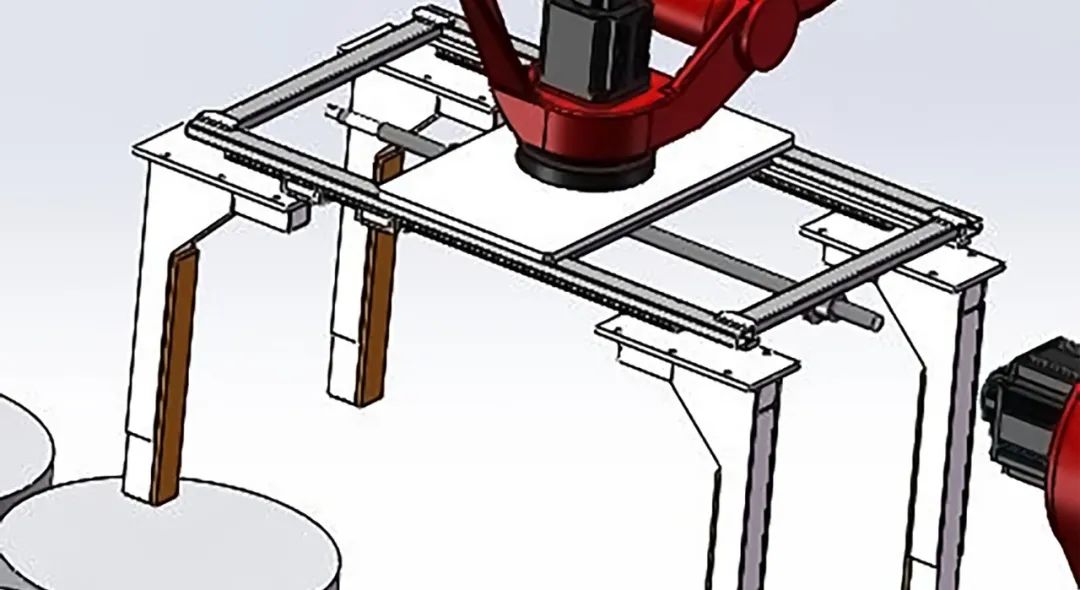

- Rubber bidirectional screw structure gripper

The robot gripper adopts bidirectional screw mechanism to control the gripper, and in order to prevent the phenomenon of products falling off in the process of grasping products or handling, and protect products from damage, the gripper surface is specially made of rubber material, double guarantee, safe and reliable.

III. Advantages of the scheme

Fully automatic handling code stamping operation

Hy1165b-315 handling robot workstation can completely replace manual to carry out non-woven material handling, stacking work, not only to ensure the personal safety and work value of employees, but also to solve the quality and integrity of the product quality and other problems, improve the production efficiency of the whole non-woven production line.

In addition, Yunhua intelligent will carry out one-to-one teaching and provide lifelong maintenance services, customers can master the operation method after simple training, to help customers achieve “efficient, safe and complete” automatic handling and stacking operations.

Yooheart can provide rapid deployment, security and efficient automation solution, more and more industry upstream and downstream manufacturers in the active deployment Muscovite, mica muscovitum intelligent robot into the production line, welding, assembling, handling, stacking and cutting work, the next Muscovite, mica muscovitum intelligence will help more enterprise can upgrade the industry, science and technology assignment.At the same time, we will continue to share more mature applications of intelligent robots.

Post time: Mar-01-2022