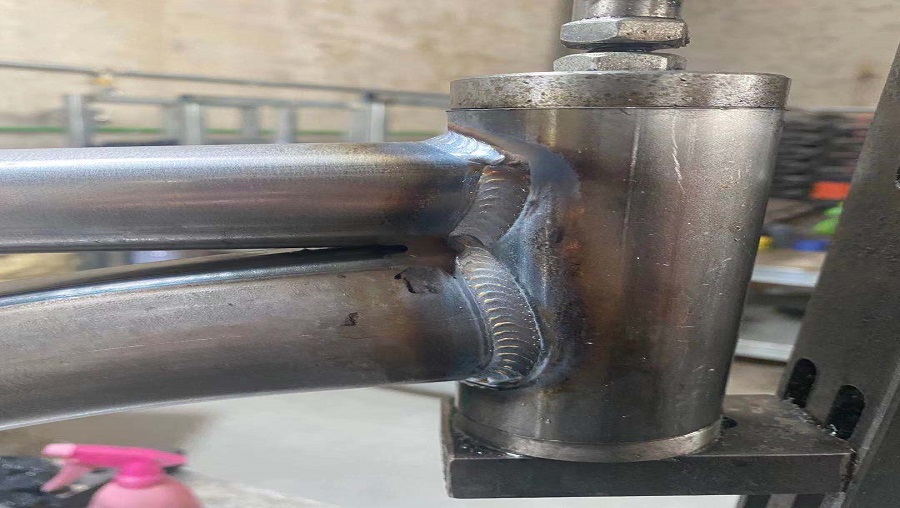

Fish scale welding is a welding technological process which is known as its welding plane is fish scale. Nowadays, fish scale welding is the highest technique in welding fields. Before the industrial robot was applied in the field of welding, only skillful artisans could weld such a good-looking weld.

Why is the fish scale welding process the most difficult? That is, during the welding process, workers need to select the welding point, turn on the electricity, and beat the arc with the welding rod head to melt the flux in the welding rod, and then swing the welding tongs slightly from left to right to melt the welding center evenly in the welding position, then the effect of good welding will be like the fish scale. The problem with artificial fish scale welding is hand shaking, which will cause molten pool tungsten.

Nowadays, welding robots can also allow you to have such an exquisite fish scale welding process. Welding robots can perform fish scale welding with the following characteristics:

First, keep welding parameters accurate. Welding parameter is the key of welding quality, so that it is very necessary to choose the accurate welding parameter. Second, keep angle and position accurate. The welding gun angle and welding position will affect the final welding forming, but the welding robot with set parameters can always keep the same Angle and position to reduce errors. Third, holding accurate time. The programmed welding robot can start and close the arc according to the set time, which can better grasp the opportunity.

Post time: May-09-2021