Part 1 About ARES Robot

About Us

Xuancheng Ares Intelligent Robotics (Ares Robot) is a robotics company integrating R&D, production, sales, application and service.

Mainly provides various models of industrial robots and robot application workstations with a load range of 3KG-300KG, and undertakes various automated production line integration and solutions.

As the earliest company to produce purely domestic industrial robots, Ares Robot has more than ten years of technical accumulation, a first-class technical team, producing and selling more than 30,000 industrial robots, rich experience in integrated applications in many fields.

Ares Robot independently developed high-precision RV reducers and control systems, obtained more than 100 technical patents of various types, and our products have passed IOS9001 and CE dual system certifications.

Ares Robot is committed to building a first-class domestic robot brand, allowing every factory to use robots and create value for users and society!

Application Experiences

Robot working Station Show

Part 2 Project Introduction

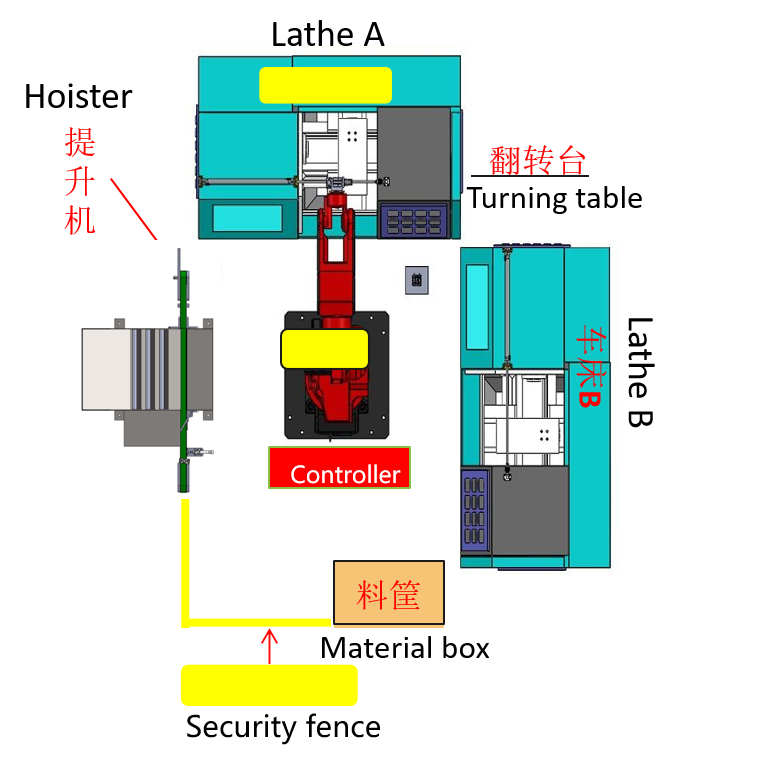

ARES Robot Loading and Unloading system Technical Project Overview

CNC Machine Machining Part

Technical Data and Description

- 1, Operation mode

Operation Form: semi-automatization

- 2, Technological process

Hoister loads material

Manually pour the material into the hoist bin

- 3, Robot loads and unloads materials

Robot loads and unloads materials. Claw B takes lathe A material

Gripper B will put the material on the turning table, turning table

Gripper B takes the material of the turning table, gripper A takes the material of lathe B, gripper B puts the new material

Gripper A puts the new material into the box

Repeat the above steps

Note: The robot gripper is designed for two working station, and there is no time interference in the processing of 2 CNC lathes!

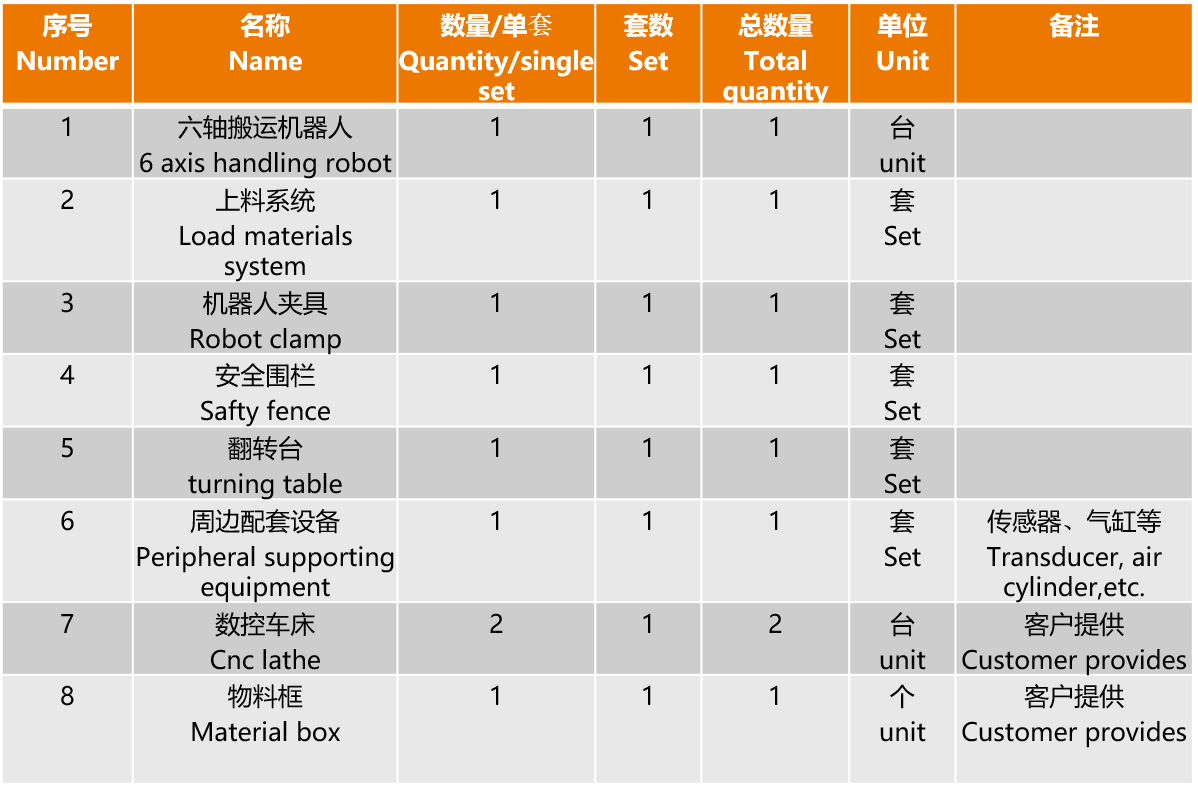

Main Equipment and Function

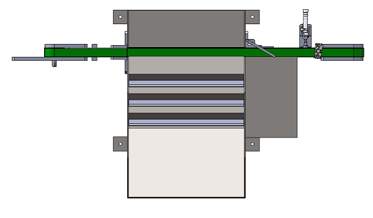

Hositer general view

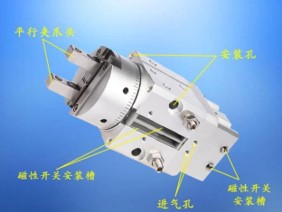

Schematic diagram of rotary clamping cylinder

Part 4 Installation, Debugging and Training

Before delivery, the robot system will be assembled and fully functional tested in Xuancheng ARES Intelligent Robotics Co., Ltd. The customer will ship the workpiece to our company for pre-acceptance before leaving the factory. During the pre-acceptance, the customer operators will receive initial technical training.

The installation plan and technical requirements will be submitted to the customer 20 days before the installation, and the customer shall make timely preparations according to the requirements. Our company will send engineers to install and debug the system at the customer's site, and complete programming and debugging, personnel training and mass trial production under the condition that the customer ensures sufficient debugging parts. Our company trains the engineering and technical personnel of programming, operation and maintenance of robot system for customers. The trainees should have certain computer basis.

During installation and debugging, the customer shall provide necessary tools, such as lifting equipment, forklift truck, cables, and hammer drill. Temporary assistance personnel shall be provided during unloading and installation.

ARES is responsible for the guidance of equipment installation, commissioning and related personnel training, training maintenance and operation workers. The demander selected personnel to operate, ultimately to achieve their own operation and maintenance of the equipment.

Training content: equipment structure principle, common electrical troubleshooting, basic programming instruction introduction, programming skills and typical parts programming methods, equipment operation panel introduction and precautions, equipment operation practice, and Q&A.

If meet special situation, Both sides negotiated settlement

Part 5 Environmental Requirement

Environment

Power Requirement

Ambient temperature: Operating temperature 0~45℃

Shipping and storage temperature -20~60℃

Temperature coefficient 1.1℃/min

RH: Usually the ambient temperature is 20% ~ 75%RH (no condensation occasions); In the short term (within 1 month). Less than 95%RH (in case of no condensation).

Requirements

Part 6 Quality Assurance Service

The quality guarantee period of the core parts of this equipment is 1 year or 2550 hours, whichever comes first.

Xuancheng ARES Intelligent Robotics Co., Ltd can repair or replace parts free of charge(EXW) if it is damaged in normal use and the equipment is within the warranty period (consumables, maintenance products, safes, indicators and other consumables specially designated by our company are not subject to this limit).

For wearing parts without warranty, our company promises the normal service life and supply price of wearing parts, and the equipment has a stable supply channel of equipment for up to five years.

After the end of the warranty period, our company will continue to provide lifelong paid service, provide comprehensive technical support and required equipment accessories.

Part 7 Check and Acceptance Standard

Pre-check and acceptance

Pre-check and acceptance shall be in Xuancheng ARES Intelligent Robotics Co., Ltd, attended by relevant personnel from both sides. Pre-check and acceptance shall be conducted according to the key accuracy of the workpiece provided by the customer to achieve the operation target, and the pre-check and acceptance inspection report shall be issued, and the goods shall be delivered after passing the acceptance. In order to ensure the smooth pre-check and acceptance, the customer shall provide 4 sets of spare parts +1 set of finished products for normal production.

Final Check and Acceptance

Final acceptance is approved by the customer department inspection (including equipment configuration, appearance inspection and no-load functions, etc.), and the control system function demonstration approval. After all installation and debugging are qualified, the final acceptance of the equipment shall take effect with the signature of the acceptance representatives of both parties.

The main criteria and basis for final acceptance are as follows:

1. 4 main components within the scope of technical agreement for continuous operation, and the product quality meets the technical requirements.

2. The equipment shall meet the requirements of relevant national standards and technical agreements.

Part 8 Files with Station

Installation drawings: Construction drawing of equipment foundation, Equipment installation drawing

Design drawings: General equipment drawing, wiring diagram

Instructions manuals: operation and maintenance instructions, Robot instruction Manual