Speaking of joints, mainly refers to the most important basic parts of industrial robots, but also the core parts of motion: precision reducer.This is a kind of precise power transmission mechanism, which uses the speed converter of the gear to decelerate the rotary number of the motor to the desired rotary number, and get a larger torque device, so as to reduce the speed and increase the torque.

At present, there are not many manufacturers that can provide large-scale and reliable precision speed reducer. Most of the global market share is held by Japanese companies: Nabtesco’s RV reducer accounts for about 60%, Harmonica’s Harmonic reducer accounts for about 15%, and SUMITOMO (the proportion is not available).The proportion of applications, especially in robotics, is overwhelming.

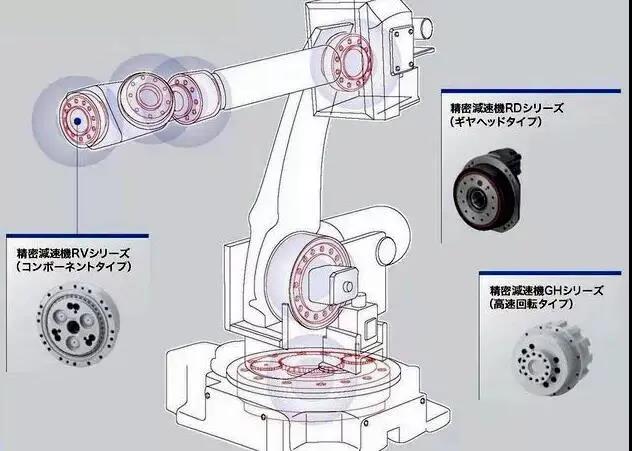

Nabtesco precision reducer

Nabtesco was founded in September 2003 and seems to be a post-00s company.It was actually a merger of two Japanese companies, Teijin Seiki (founded in 1944) and Nabco (which produced Japan’s first automatic doors in 1956).As manufacturers of motion control systems and components, both companies have mastered high-end core technologies in their specific areas of business and control a high market share. Nabtesco has been the industry leader in Japan and the world since its establishment.Most robot manufacturers around the world have benefited from Nabtesco’s patented RV reducer with success.

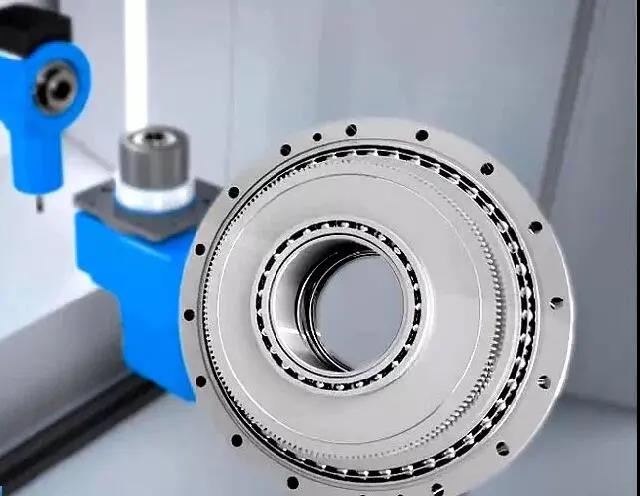

As the world’s largest manufacturer of precision cycloid pin gear reducers, Nabtesco manufactures high performance reducers, hollow shaft reducers, as well as single shaft servo actuators and controllers.Its precision equipment has high torque, high rigidity and high impact load resistance, while having high precision and very low return clearance.

Each joint uses a different reducer product

At the beginning of its establishment in 1944, THE company started its business in aircraft manufacturing. In 1947, it entered the field of textile machinery manufacturing. In 1955, it began to manufacture aircraft parts, and in 1959, it expanded to machine tool manufacturing.Nabtesco’s RV reducer, the predecessor of the main product of The DrI machine, began to be used as the core component of the driving motor of excavating equipment in the 1970s.In the early 1980s, in response to the requirements of the world’s major robot manufacturers, THE RV reducer has been improved to make it more accurate and reliable, in line with the strict requirements of the robot manufacturing industry.After obtaining the patent of precise cycloidal gear RV reducer, it began mass production in 1986, and began to support the joint application of modern industrial robots.

Harmonic Drive

Harmonic Gear Drive is a gear drive system that relies on wave generator to make flexible gear produce controllable elastic deformation, and meshing with rigid gear to transfer motion and power from scratch.The harmonic drive was patented by Clarence Walton Musser(1909-06-08, 1998) in 1957 (US Patent Number 2906143). In addition, the inventor, who worked for 15 years in the US Department of Defense, had 250 major inventions in his lifetime.Examples include military recoilless rifles, aircraft catapults, underwater explosive testing instruments and so on.

It sounds like a big industry category, but harmonic Drive is Harmonic Drive Systems Inc.The trademark.In 1960, USM successfully put harmonic drive into use for the first time, and Hasegawa Gear Works, Ltd. (Hasegawa Gear Works, Ltd.) later obtained the USM production license.In October 1970, Hasegawa and USM formed Harmonic Drive Systems Inc. in Tokyo with a 50-50 investment.Eight hexagrams: The president of Hasegawa was named Tanegawa Tooth car, xiaobian think this name is destined to do gear…

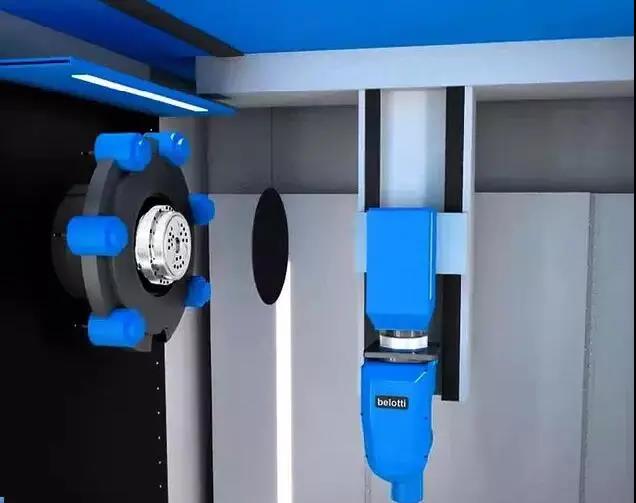

Hammer naco leading motion control of the whole enterprise, its production of HarmonicDrive combination harmonic reducer, characteristics, such as light weight small gear clearance and high torque capacity, widely used in industrial robots, robot, semiconductor, liquid crystal production equipment, photovoltaic equipment, optical instruments, precision machine tools and other cutting-edge fields.

To cover the areas of low reduction ratios that Harmonic reducers cannot achieve, the product also includes Harmonic Planetary reducers.The unique inner gear ring shape change process can make the planetary gear meshing tighter, eliminate the back gap, has reached the precision transmission error.

Wave gear speed reducer in the aerospace, energy, Marine shipbuilding, bionic mechanism, commonly used weapons, machine tools, instruments, electronic equipment, mining, metallurgy, transportation, lifting machinery, petrochemical machinery, textile machinery, agricultural machinery, and increasingly widely used in the field of medical apparatus and instruments, especially in the high dynamic performance of servo system,Harmonic gear drive shows its superiority.The electric wheels of the Apollo moon rovers were made by Hamenaco

Post time: Sep-14-2021